WEBINAR: EMC Shielding Connectors

When electromagnetic noise generated inside or outside the device interfere with the circuit inside the electronic device, creating (noise, unnecessary current may be induced to the circuits in the devices causing a malfunction or damage to high-performance electronic components which may also lead to device failure. Therefore, effective countermeasures against electromagnetic noise must be taken, especially in high-performance compact electronic equipment with high-density electronic components.

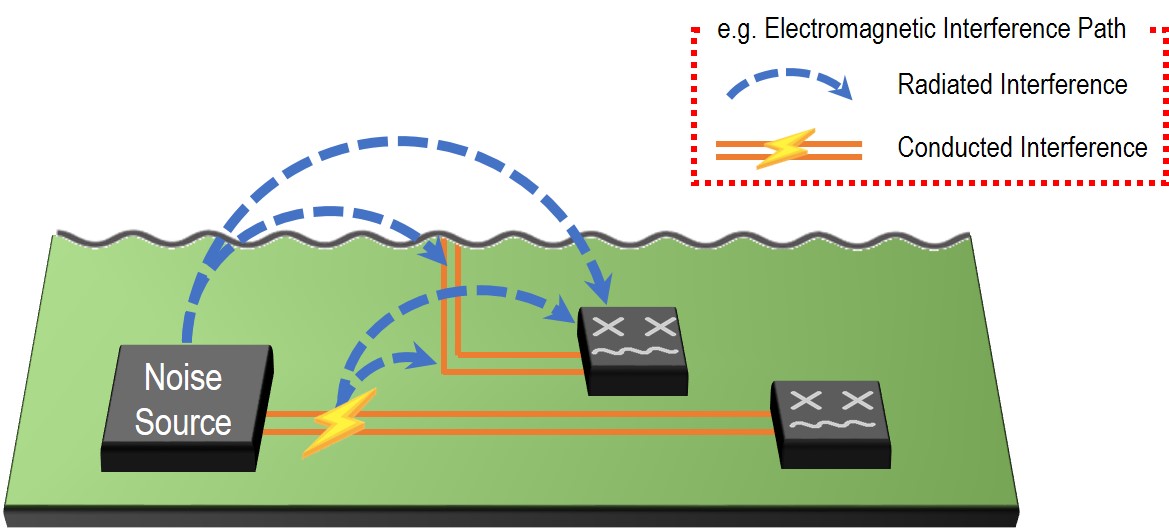

There are two types of interference-conduction paths for electromagnetic noise: “Conducted Interference” and “Radiated Interference”.

For conducted interference electromagnetic noise, which is transmitted through conductors such as cables and board traces in equipment, the interference noise can be isolated and adjusted by incorporating electromagnetic noise filter components into the circuit appropriately.

On the other hand, for radiated interference electromagnetic noise, in which electromagnetic waves are radiated as noise into a space and conducted to another circuit, it is necessary to take measures to block noise conduction in the air by using shielding.

However, if the board circuitry, including the internal connectors that connect modules, is covered with shields, it may be difficult to unmate the connectors when necessary, for example, when repairing equipment . In this case, the use of a high-performance EMC connector, which prevents electromagnetic noise in the connector itself, can provide EMC countermeasures for the connector part without sacrificing the connector mating/unmating function.

ZenShield® Connectors

ZenShield® , I-PEX's high-performance EMC shielding connector series, offers various types of EMC shielding connectors for different applications, including micro-coaxial, micro RF , board-to-board FPC , and FPC/FFC connectors.

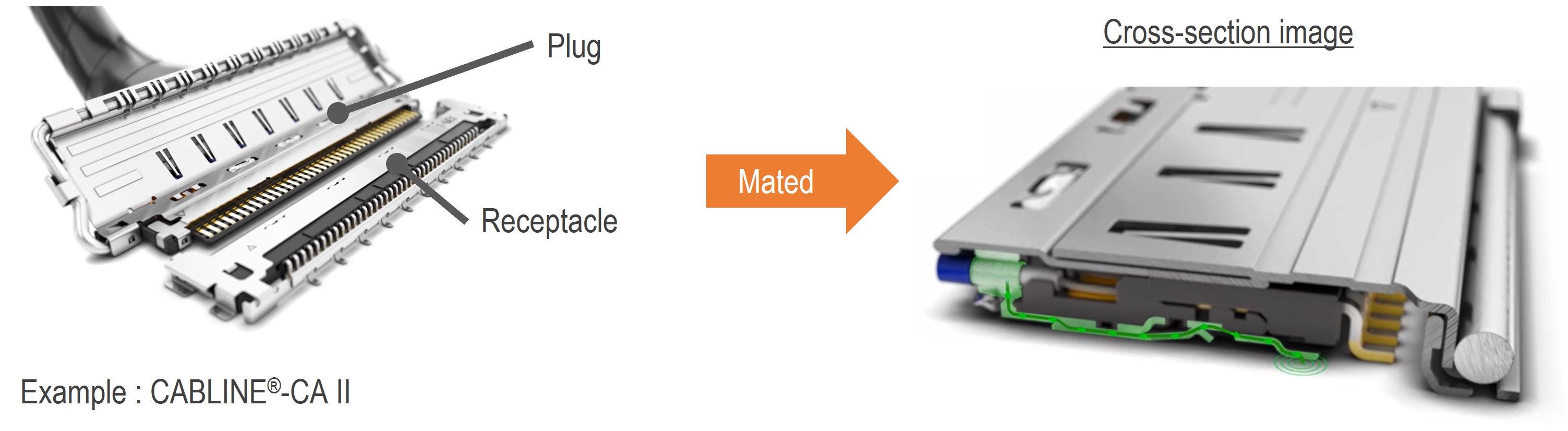

The ZenShield® connector series provides 360-degree EMC shielding to prevent electromagnetic noise radiation not only from the contact points of the plug and receptacle, but also from the board mounting part (SMT positions) of the signal terminals. In addition, the shields of both the plug and receptacle are properly grounded at multiple points when the connectors are mated, and are also properly grounded at multiple points on the board. This design protects the signal in the connector from external electromagnetic noise and prevents the signal in the connector from radiating electromagnetic noise to the outside. This unique shielding design provides the I-PEX ZenShield® connector series with excellent EMC countermeasures.

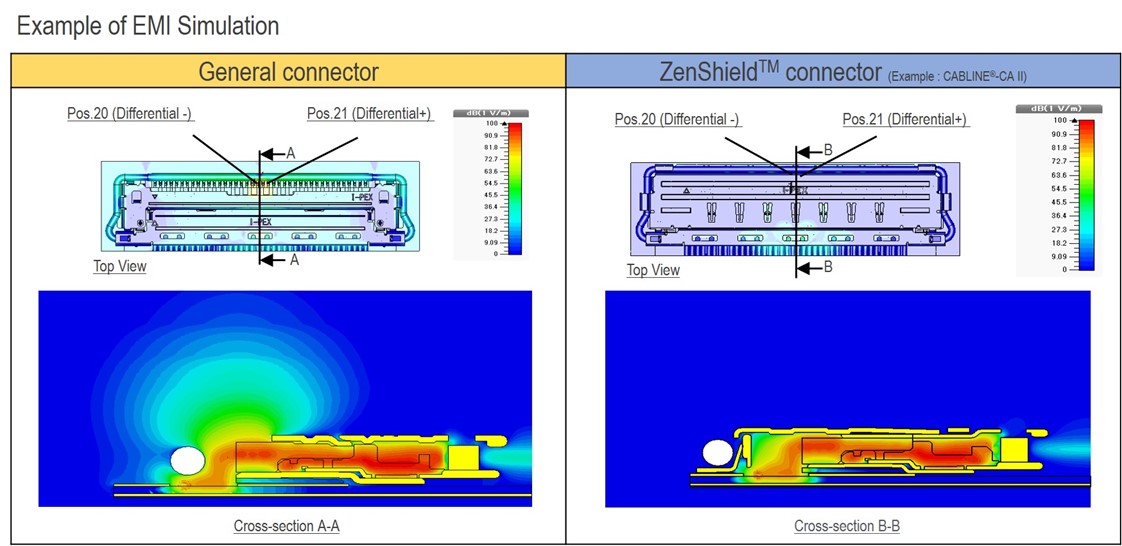

The effect of the EMC shielding is shown more clearly in this electromagnetic interference (EMI) simulation, comparing a general connector with a ZenShield® EMC shielding connector. The left figure shows a cross-sectional view of a general, partially-shielded micro-coaxial connector, and the right figure shows a ZenShield® EMC shielding connector, CABLINE®-CA II.

The leakage from the signals is displayed in light blue.

In the general connector, on the left, leakage from the signals emanates out from the connector through the contact tail areas. In the ZenShield® EMC shielding connector, on the right, the radiation from the signal pin is restricted to the area within the connector and its shield. Outside of the connector, there is almost no light blue emissions.

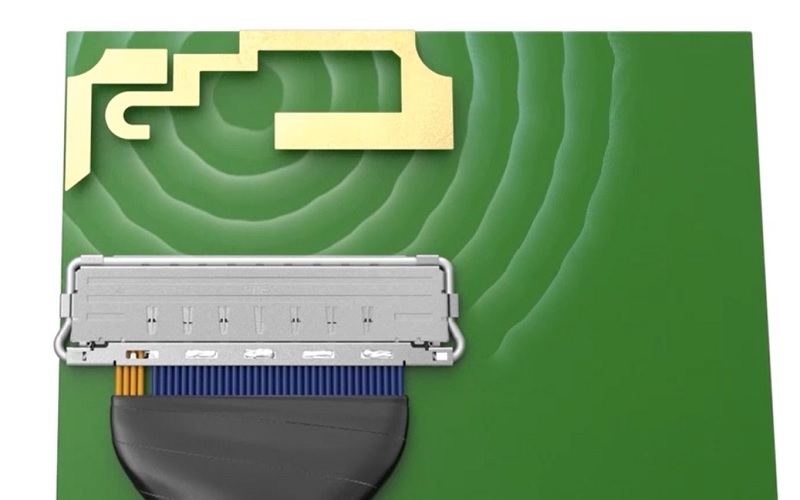

Because the connector itself can significantly reduce EMI due to this design, ZenShield® allows for a flexible board design, such as placing the connector close to the antenna, especially in high-performance electronic equipment with wireless communication functions that are required to address intra-system EMC issues.

With these design features, the connector itself provides significant mitigation of EMI. ZenShield® gives board designers more flexibility for designing the board by allowing the connectors to be placed in close proximity to sensitive subsystems, such as transmit/receive antennas, that are commonly found in high-performance wireless communication systems.