I-PEX High-Temperature Connector Products

Electric power is becoming mainstream due to technological innovations in automated driving and the growing use of environmentally friendly electric vehicles (EVs). In order to cope with the increased electronics used in automobiles, automotive developers must address high-speed data transmission, and high-current and high-voltage situations while reducing the size and weight of components and saving space.

In addition, the increased number of modules installed means increased heat generated due to high currents. It also means increased heat generation density inside the housing of the modules, so the use of heat resistant components is ever more important.

I-PEX has a large lineup of general-purpose connectors rated at 85°C and products designed for consumer devices, but to address requirements in the automotive field, we have developed a number of products that can handle high temperatures, from 105°C to 125°C. And, we will continue to add to our line-up of connectors that operate reliably in high temperature environments.

Matrix of high-temperature resistance recommended connectors

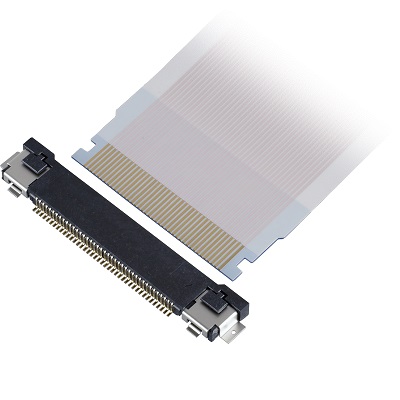

| Product type | Micro-Coaxial Connectors | RF / Coaxial Connectors | |||

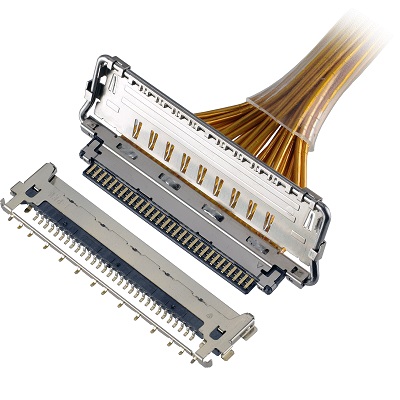

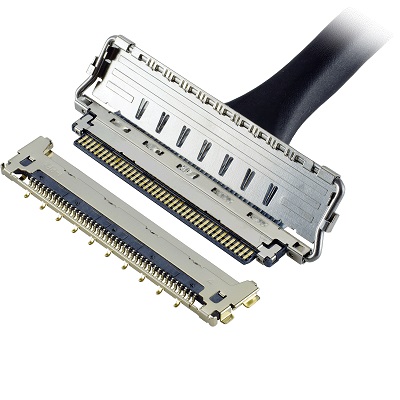

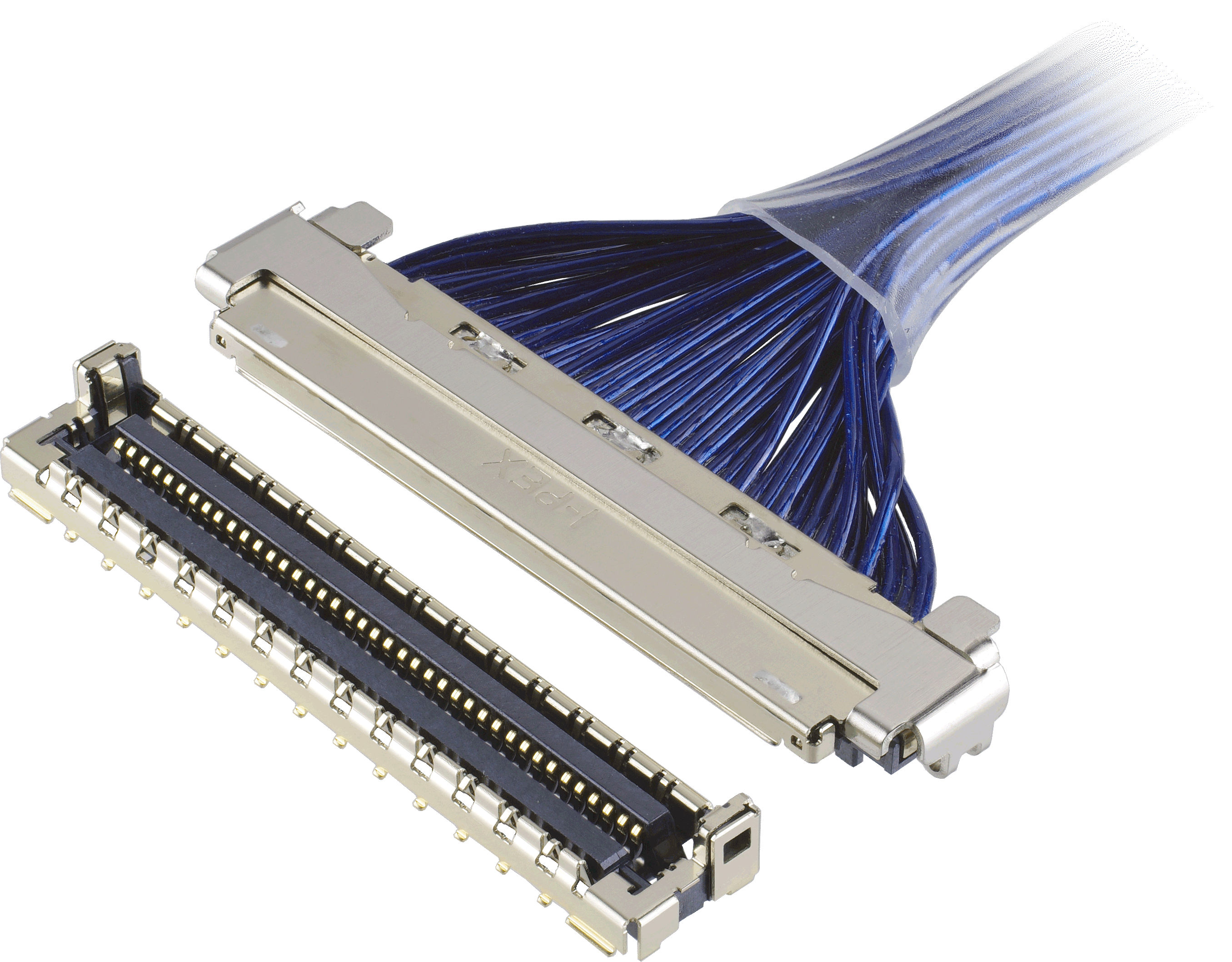

| Product Name | CABLINE®-VS II | CABLINE®-CA II | CABLINE®-CA II PLUS | CABLINE®-UM | MHF®-TI |

|

|

|

|

|

|

| Heat resistance | 105℃ | 105℃ | 105℃ | 105℃ | 105℃ |

| Pitch | 0.5 mm | 0.4 mm | 0.4 mm | 0.4 mm | - |

| Height (MAX) | 1.2 mm | 1.1 mm | 1.2 mm | 2.35 mm | 3.65 mm |

| Depth | 6.7 mm | 6.2 mm | 6.7 mm | 5.0 mm | - |

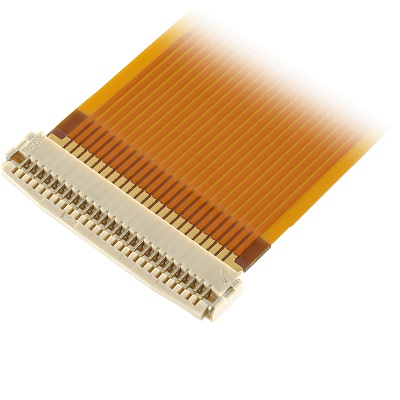

| Product type | FPC/FFC Connectors | |||||

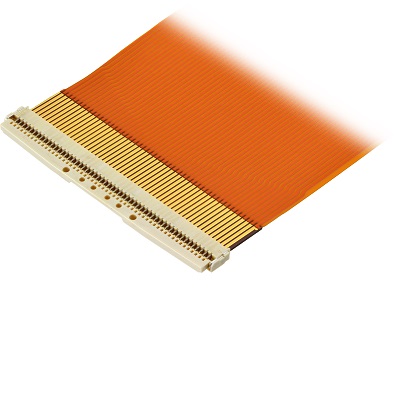

| Product Name | MINIFLEX® 5-BFN II | MINIFLEX® 5-BFN II LK | MINIFLEX® 5-FF | EVAFLEX® 5-VS Type CH | EVAFLEX® 5-SE-G VT | EVAFLEX® 5-SE |

|

|

|

|

|

|

|

| Heat resistance | 125℃ | 125℃ | 125℃* | 105℃ | 125℃ | FFC:85℃ FPC:125℃ |

| Pitch | 0.5 mm | 0.5 mm | 0.5 mm | 0.5 mm | 0.5 mm | 0.5 mm |

| Height (MAX) | 1.1 mm | 1.1 mm | 2.75 mm | 2.0 mm | 6.9 mm | 2.7 mm |

| Depth | 3.5 mm | 4.0 mm | 7.2 mm | 4.97 mm | 4.1 mm | 6.1 mm |

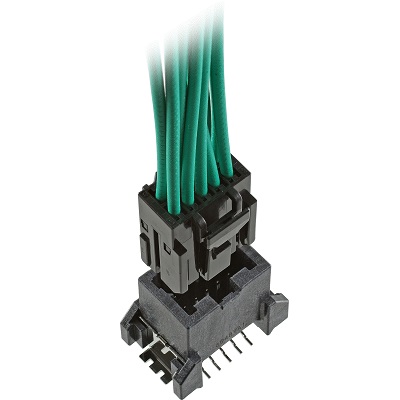

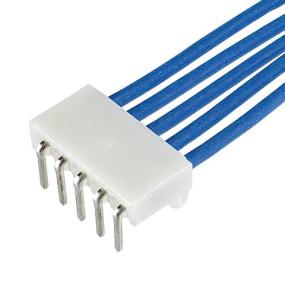

| Product type | Power Connectors / Terminals | |||||||

| Product Name | ISH® | IARPB® | AP-10 | AP-TSS10, AP-LT10 | ||||

| Type | Horizontal | Horizontal Type-Hybrid | Vertical | Wire to Wire | Horizontal | Vertical | Vertical | Vertical |

|

|

|

|

|

|

|

||

| Heat resistance | 125℃ | 125℃ | 125℃ | 125℃ | 125℃ | 125℃ | 105℃ | 125℃ |

| Pitch | 2.0 mm | Signal: 2.0 mm Power: 3.8 mm |

2.0 mm | 2.0 mm | 2.5 mm | 2.5 mm | - | - |

| Height (MAX) |

(1 row) 7.4 mm

|

13.6 mm |

20.75 mm |

(1 row) 8.0 mm

|

(2/3/4/5P) 3.5 mm

|

8.7 mm |

13.6 ~ 16.1 mm

|

8.0 mm |

(*Only Specified Products)

Features of I-PEX high-temperature connectors

I-PEX has designed high-temperature connectors by making full use of our vast experience, so that they can be used safely even in severe environments where high temperatures and long hours of operation are anticipated.

1) Material Selection

I-PEX selects materials with excellent workability, dielectric properties, and thermal conductivity, as well as stress relaxation characteristics that stabilize spring characteristics even in high-temperature use environments, and materials that can ensure consistent contact. Most of our products are made of phosphor bronze contact material, but we also use Corson alloy for high-temperature products, which is a stronger material without sacrificing the high electrical and thermal conductivity inherent in copper.

2) Design

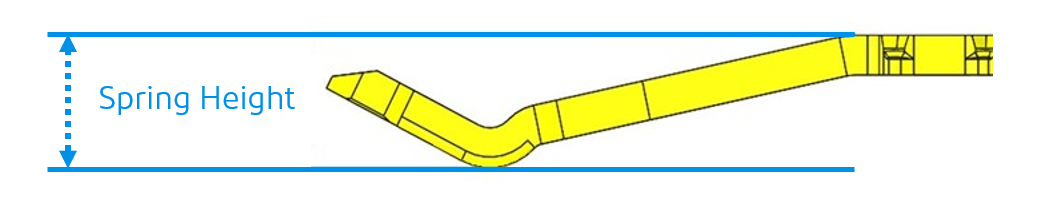

To obtain stable electrical contact, a certain level of contact pressure is required between mutual contacts. The contacts are made of a metal material and are designed in a spring shape. We focus on designing connectors that make good use of spring characteristics so that they can return to their original position and maintain contact force even during connector insertion, removal operations and stress relaxation.

Typical example: EVAFLEX® 5-SE-GVT

The contact shape has sufficient deflection (height) to maintain contact pressure even after stress relaxation.

3) Reliability Test

I-PEX is equipped with the following facilities for mechanical performance and environmental testing, as well as conducting reliability testing.

Reliability Test Facilities

|

Double Chamber Incubator  |

Rapid-Rate Thermal Cycle Chamber  |

|

Compound Environment Test  |

Compound Environment Test  |

Reliability test for high-temperature products

I-PEX conducts the following reliability tests on high-temperature products.

|

Test Item |

Testing Method |

Measurements |

||

|

Mechanical |

Vibration |

3 mutually perpendicular directions |

Contact resistance Electrical discontinuity Appearance |

|

|

Shock |

Max. G:50 G |

Contact resistance |

||

|

Environmental |

||||

|

Heat Cycling |

Standard Test |

High Temp Test |

Contact resistance |

|

|

Temp : -10 ⇔ 85℃ |

Temp -55 ⇔ +125℃ Time : 30mins cycle (Transition 5mins. MAX) No. of cycle : 100 cycle |

|||

|

High Temp Life |

Standard Test |

High Temp Resistance | Contact resistance Appearance |

|

|

Temp : 85 ℃±2 ℃ |

Temp : 125℃±2℃ Duration : 1000 hours |

|||

|

Humidity |

Temp : 40±2 ℃ |

Contact resistance Insulation resistance Electric withstanding voltage Appearance |

||

| Humidity Cycling) |

Temp-10~+65℃ Humidity : 90~98 % RH, Cycle : 10 cycle (240 hours) |

Contact resistance Insulation resistance Electric withstanding voltage Appearance |

||

| Salt Water Spray | Temp : 35±2℃、 Salt water density 5±1 % [by weight] Duration : 48 hours |

Contact resistance Appearance |

||

| H2S Gas | Temp : 40±2℃ Humidity : 80±5 % RH Gas : H2s 3±1 ppm Duration : 96 hours |

Contact resistance Appearance |

||

(Only Specified Products)

In addition, we will propose more effective test items and measures to meet the customer's requirements for their desired conditions. For connectors that require a high level of reliability, please contact us for information on the appropriate product for your application.