Wire-to-Board Connectors and Terminals

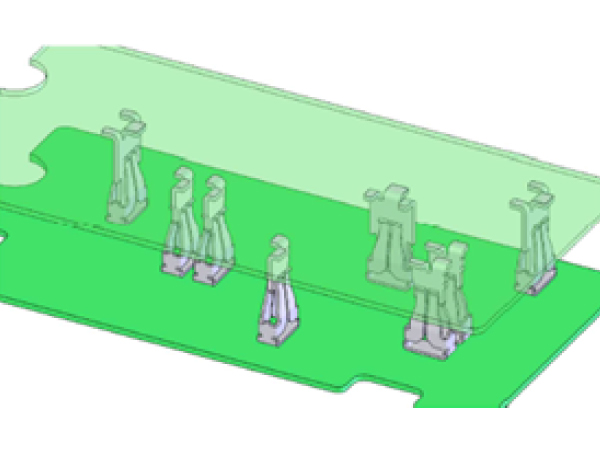

AP Series: Board-to-board power terminals

Contents:

Why select I-PEX Board-to-Board Power Terminals (AP series) for Automotive Components and industrial equipment?

- Compact design that withstands high-current and high-temperature operating environments (AP series)

- Contributes to simplification of work efficiency with a one-action mating function and to a reduction in the number of parts (AP-10)

- Reduced connector weight makes the second reflow with reverse mounting possible, contributing to a flexible SMT design (AP-TSS10&AP-LT10)

1. Compact Design that withstands High-Current and High-Temperature Operating Environments (AP Series)

Our original know-how has been utilized to achieve compact products capable of handling high currents. These products withstand the temperature rise that accompanies a large current flow, thus ensuring reliable performance, even with long-term use.

| AP-10 | AP-TSS10 & AP-LT10 |

|

|

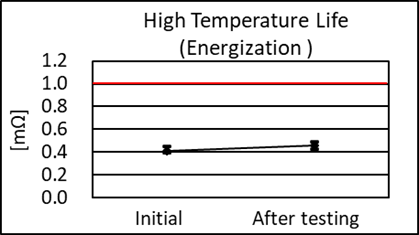

| High temperature life (Energization) Contact resistance Test condition: 105℃ (378 K) Rate current: 16 A Test time: 1,000 hours |

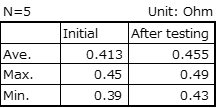

High temperature life (Energization) Contact resistance Test condition: 125℃ (398 K) Rate current: 16 A Test time: 1,000 hours |

|

|

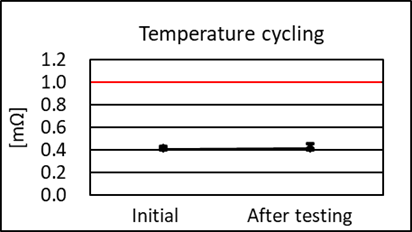

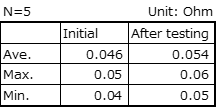

| Temperature cycling test contact resistance Test condition: -40℃(233 K) ⇔ 105℃ (378 K) 30 mins ⇔ 30 mins Test time: 1,000 cycles |

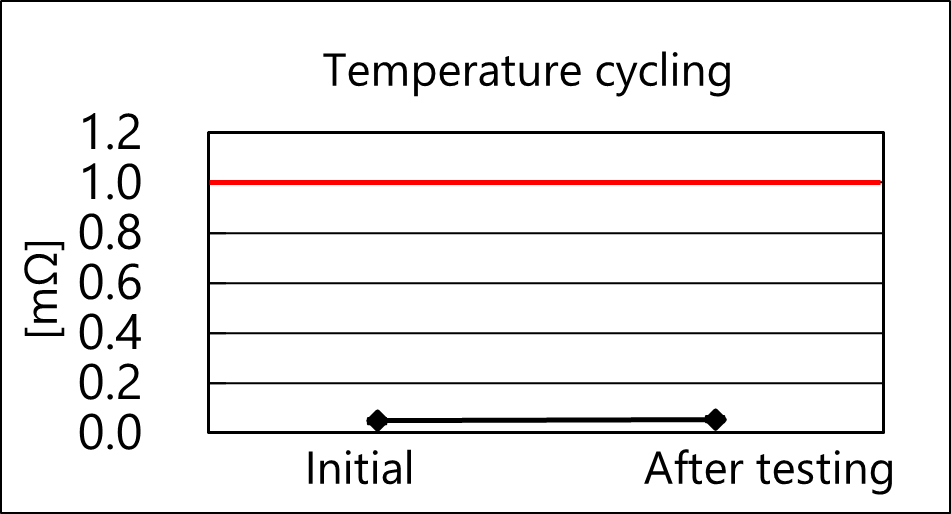

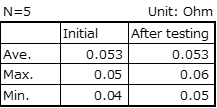

Temperature cycling test contact resistance Test condition: -40℃ (233K) ⇔ 125℃ (398 K) 30 mins ⇔ 30 mins Test time: 1,000 cycles |

|

|

2. Contributes to Simplification of Work Efficiency with a One-Action Mating Function and to a Reduction in the Number of Parts (AP-10)

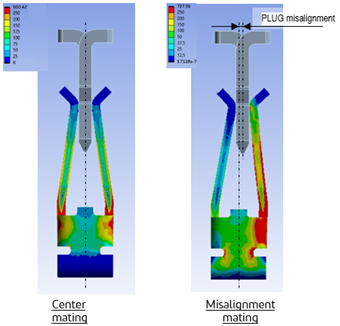

Excellent floating performance and solder stress is reduceded by the receptacle’s pronged structure. Multiple units on the same board may be used, contributing to a reduction in assembly hours.

Receptacle prongs inserts correctly, even if the plug is out of alignment. The misalignment allowance is 0.55 mm (X-axis) / 0.70 mm (Y-axis), ensuring good contact reliability.

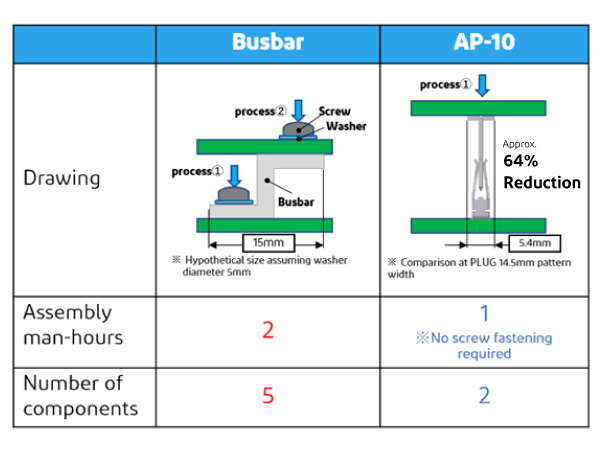

The AP-10 also reduces the board space needed compared to the conventional bus bar connection method and reduced the number of connection parts. As a total, AP-10 achieves cost advantages over the conventional bus bar connection method.

3. Reduced Connector Weight makes the Second Reflow with Reverse Mounting Possible, Contributing to a Flexible SMT Design (AP-TSS10&AP-LT10)

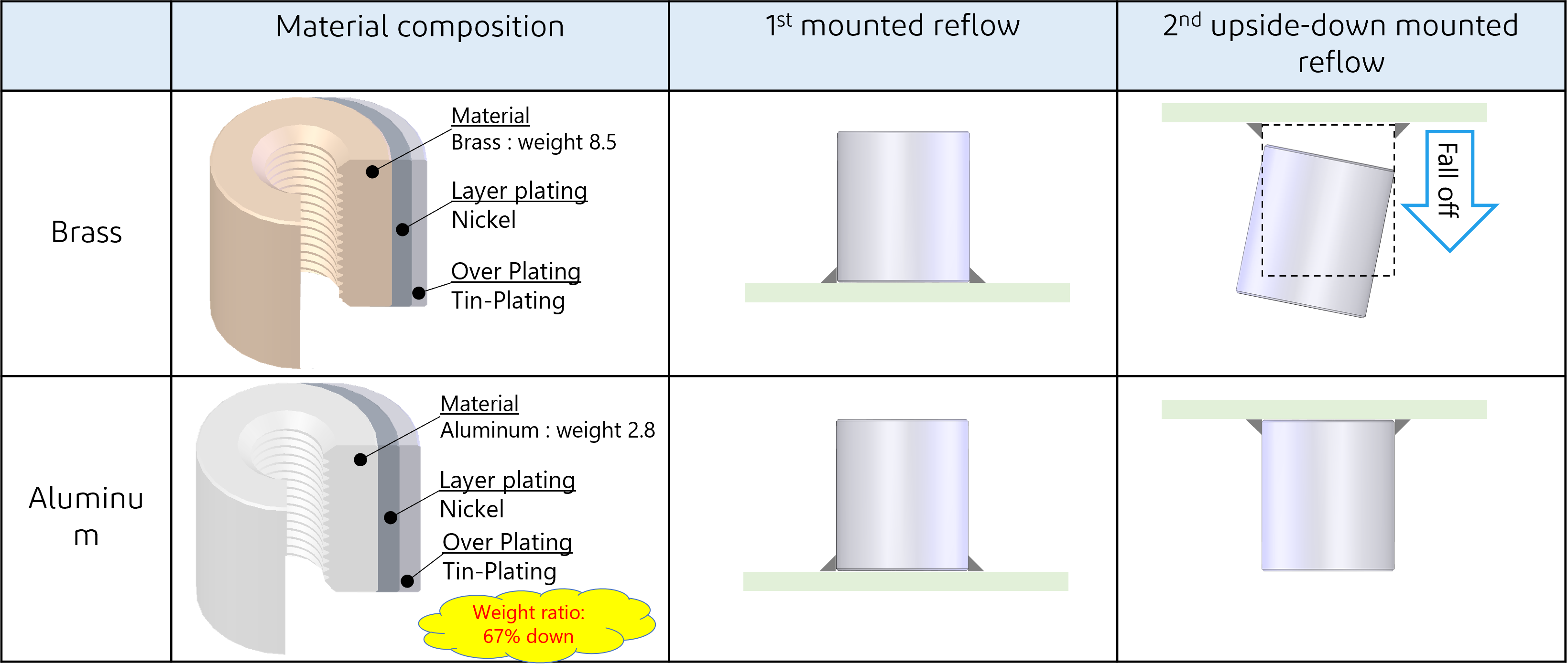

The AP-TSS10 uses aluminum for base material, which is approximately 67% lighter in of weight than ordinary brass material. It enables reverse (backside) mounting in the second reflow process. On the other hand, ordinary brass and other materials may cause components to drop due to their own weight during reflow mounting of upside-down (backside) mounting or may cause mounting defects. I-PEX's AP-TSS10 contributes to the flexibility of the mounting process and SMT design.

The features described above all contribute to total cost reduction of in-vehicle components/applications.

More information: AP-10, AP-TSS10&AP-LT10

ISFIT®: Solderless Press-Fit Terminal

Solderless press-fit type connectors are commonly used in the PCB based assembly process. Whereas conventional connectors are soldered directly on the board, press-fit connectors can be mounted using a simple press-fit method, which simplifies the process. This reduces manufacturing costs by eliminating the solder mounting process.

Solderless press-fit type connectors are commonly used in the PCB based assembly process. Whereas conventional connectors are soldered directly on the board, press-fit connectors can be mounted using a simple press-fit method, which simplifies the process. This reduces manufacturing costs by eliminating the solder mounting process.

However, the press-fit method could cause damage to the PCB and requires great press force for mounting. In order to solve these problems, I-PEX offers a completely new concept terminal: the ISFIT® series.

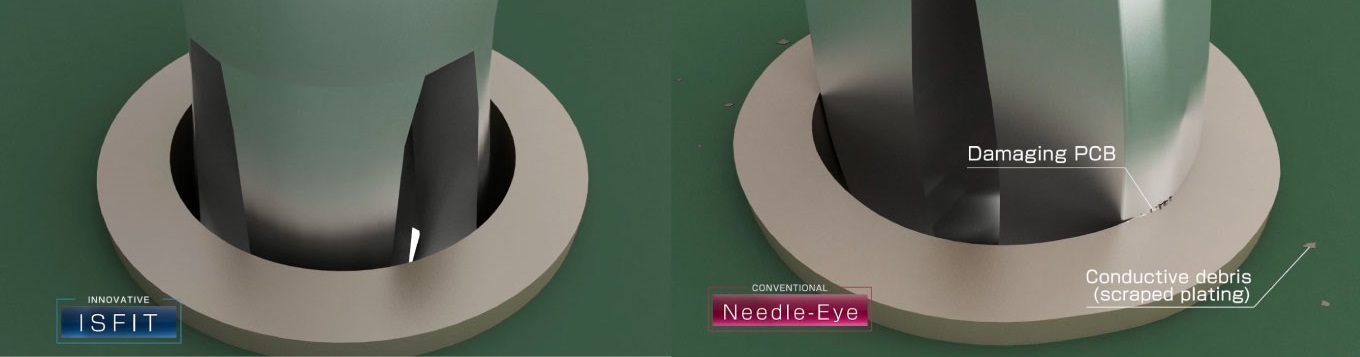

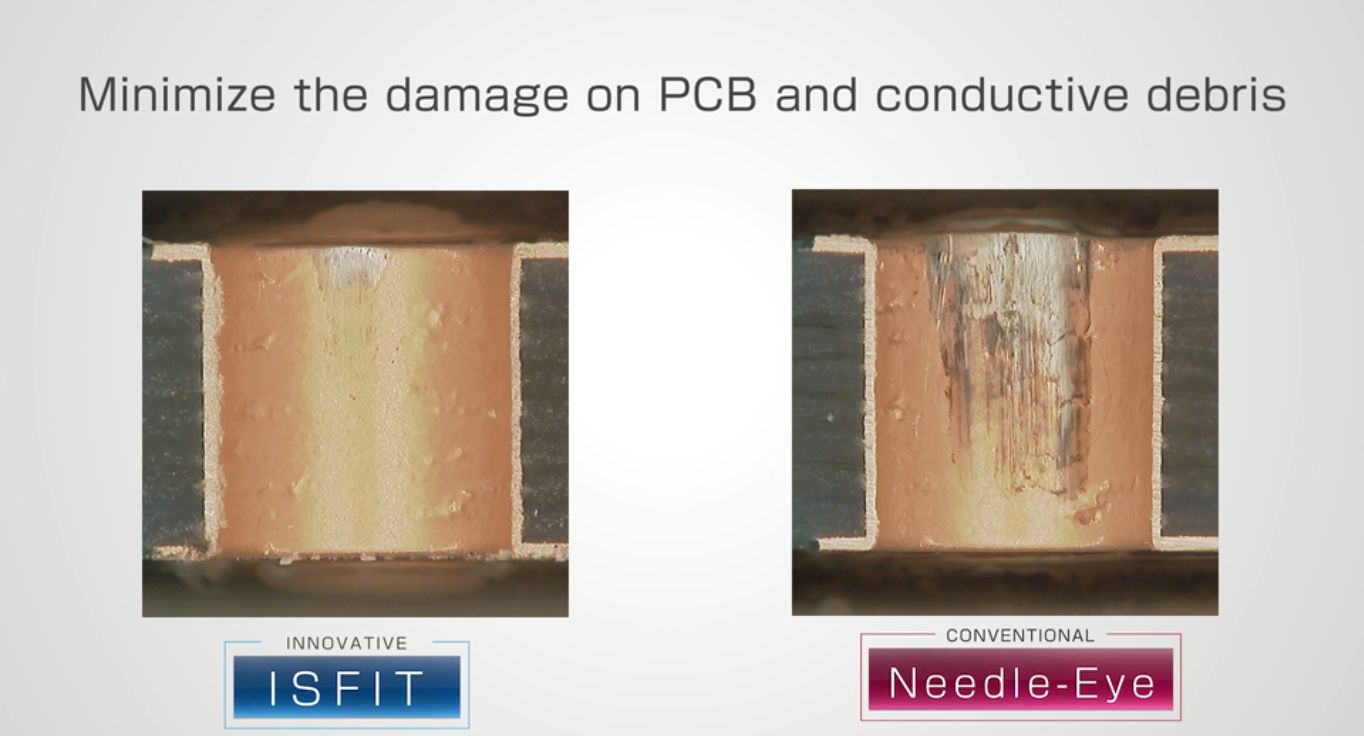

1. Eliminates Damage to PCB

Our unique terminal design with the spring structure eliminates the damage to the PCB during the insertion process.

The conventional eye of the needle type terminal without the spring structure causes damage to the PCB

through-hole edge, as well as the inside wall.

(comparison: Through-hole edge)

(comparison: Through-hole inside)

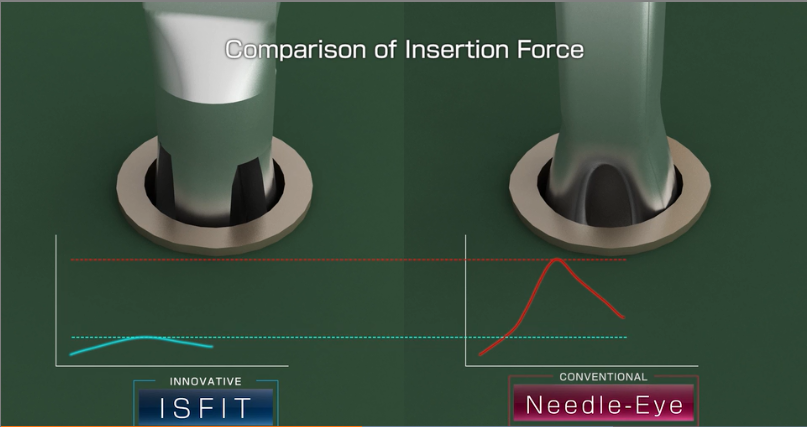

2.Requires Less Insertion Force

The ISFIT® spring structure terminals absorb the insertion force during the insertion process. It lessens the coefficient of friction compared to the eye of the needle version, keeping the insertion force lower from start to finish.

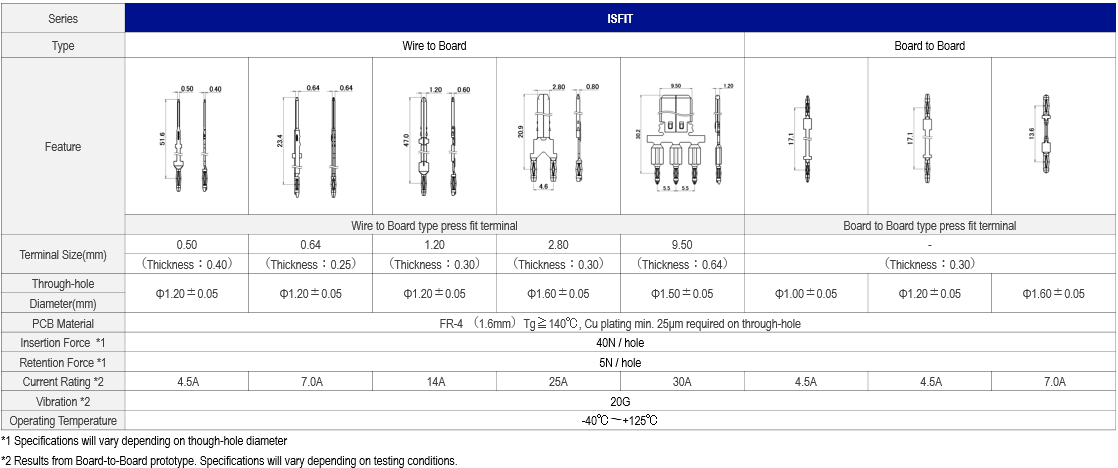

3. Terminal Lineup

Learn more about the ISFIT® Solderless Compliant Pin Terminal / Press-Fit Connector Technology.

ISFIT® Solderless Compliant Pin Terminal Video

Connectors on demand

I-PEX offers customized connectors using the ISFIT® terminal upon request. Please contact us for details.