i-Fit® Technology

i-Fit® is a unique solderless terminating technology used in the I-PEX micro RF coaxial connector (MHF®) series. The solderless production process helps to stabilize the electrical characteristics of the RF jumper harness. In addition, it makes the mechanization of the RF connector jumper harness production relatively easy, resulting in increased efficiency and high productivity. This connector is used to connect antenna modules for many communication devices such as notebook PCs, tablets, mobile phones and routers.

i-Fit® is a unique solderless terminating technology used in the I-PEX micro RF coaxial connector (MHF®) series. The solderless production process helps to stabilize the electrical characteristics of the RF jumper harness. In addition, it makes the mechanization of the RF connector jumper harness production relatively easy, resulting in increased efficiency and high productivity. This connector is used to connect antenna modules for many communication devices such as notebook PCs, tablets, mobile phones and routers.

(I-PEX RF connector product list: Click here)

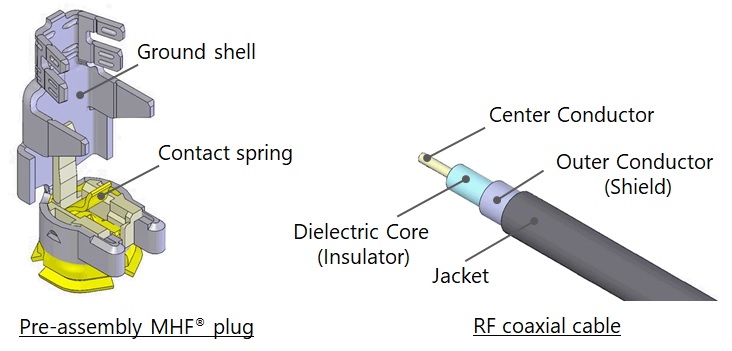

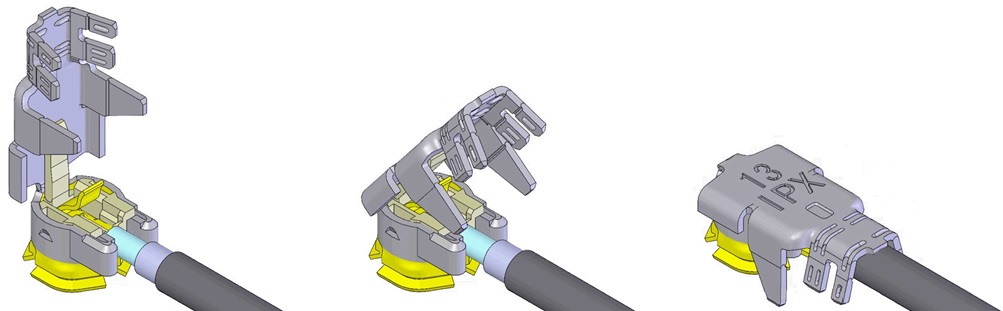

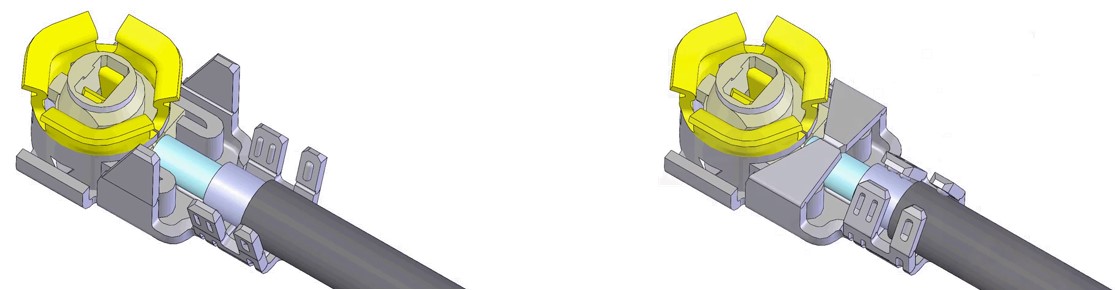

Structure of MHF® connector and RF coaxial cable

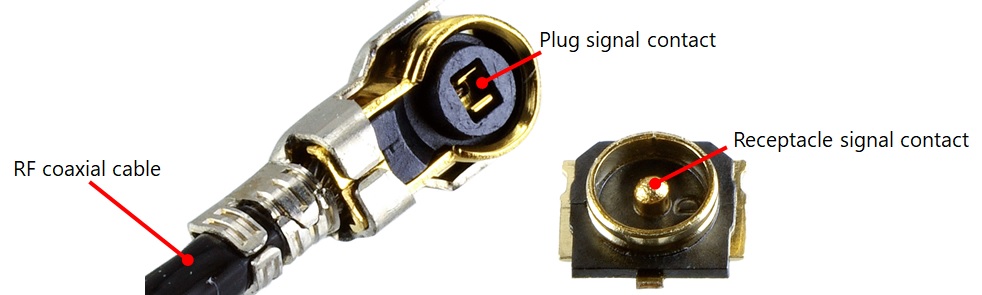

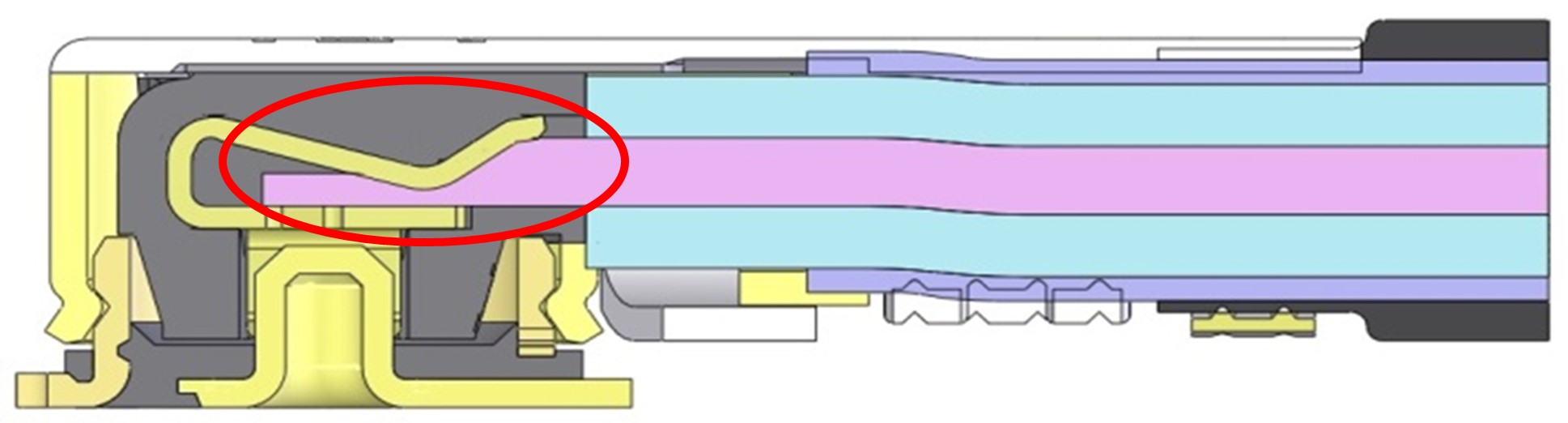

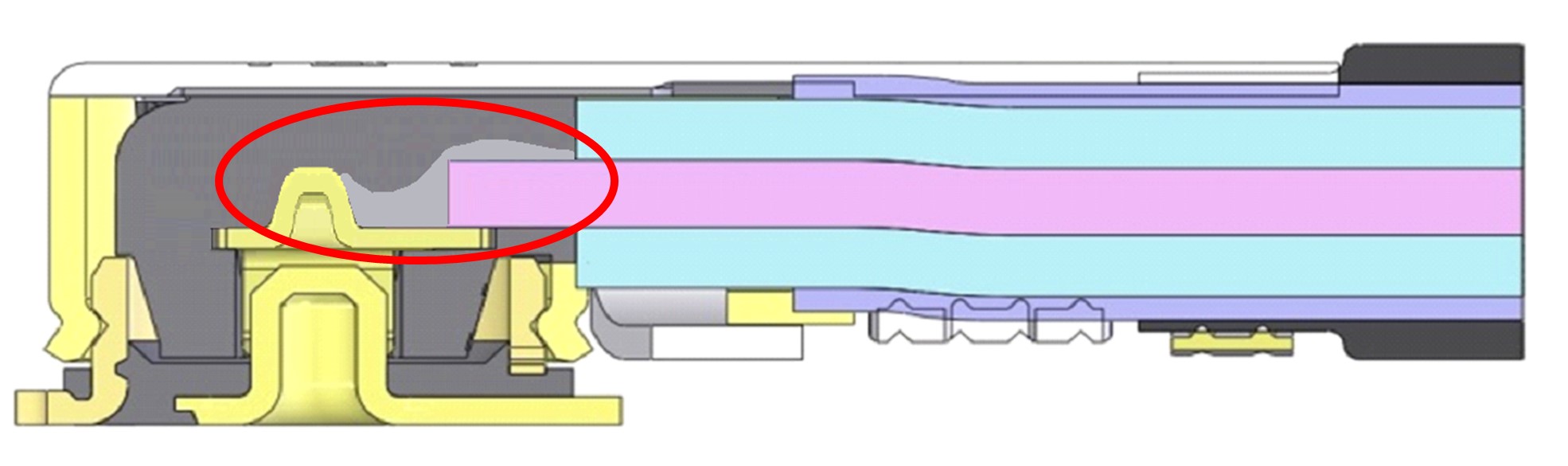

When transmitting antenna signals using an RF coaxial cable connector harness, the RF coaxial cable center conductor must be electrically connected to the signal contact of the receptacle which is mounted to the PCB via the plug signal contact. Using i-Fit® technology, the MHF® connector conducts the RF signal by sandwiching the RF coaxial cable center conductor with the plug contact spring. Also, the plug metal ground shell firmly crimps the outer conductor and the jacket of the RF coaxial cable and electrically connects the ground, while providing adequate cable retention force without soldering.

Features of MHF® connector jumper harness

-

Stable electrical characteristics

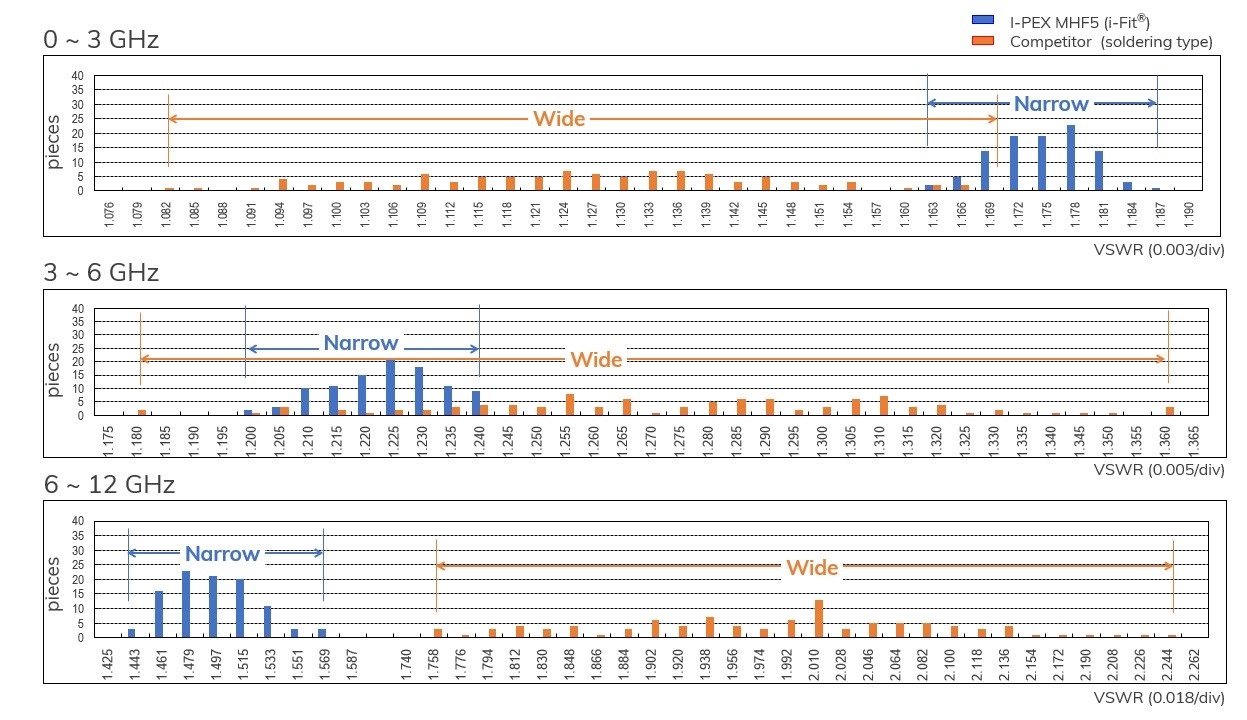

By connecting the center conductor of the RF coaxial cable with a press-formed contact spring, it is possible to suppress variations in the internal shape of the connection and achieve excellent uniformity of electrical characteristics.

On the other hand, the solder connection solidified shape is affected by changes in many environmental conditions such as: soldering method, operator, solder material, amount of solder applied, temperature of solder and process speed. In general, it is difficult to maintain the uniformity of the electrical properties of a product compared to the connection method using contact springs, and it is more likely that the performance will vary from product to product.

Using i-Fit® technology, the variation of VSRW results of I-PEX MHF® is concentrated in a narrow range compared to the equivalent solder connection type RF connector and has excellent uniformity of electrical performance for each product.

-

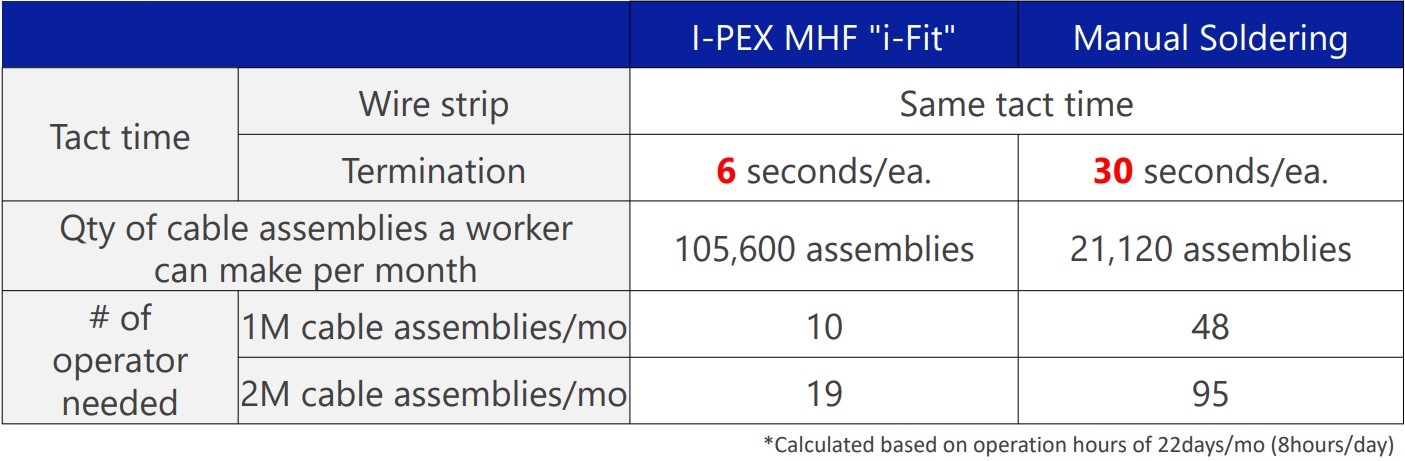

High productivity

The mechanization of the I-PEX MHF® connector RF jumper harness production process is relatively easy as it does not require a soldering process to terminate the cable, resulting in increased efficiency and high productivity.

-

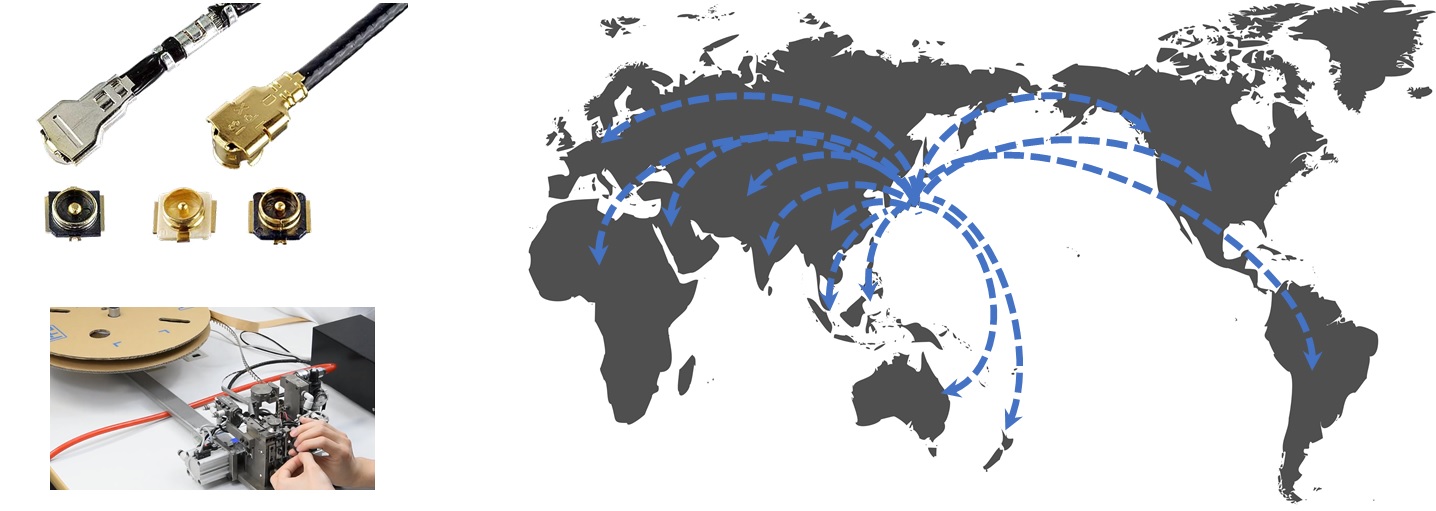

Industry adoption and high availability

The MHF® series connector has had shipments in excess of 2 billion units, and a large amount of RF harnesses and antennas with MHF® connectors are now on the market. In addition, I-PEX i-Fit® technology has enabled antenna and harness makers to have the ability to terminate MHF® products in local production facilities. With over 1,000 termination machines in the field, more than 100 customers produce MHF® harnesses and antennas ensuring quality when using genuine MHF® components. Therefore, I-PEX MHF® can be supported and supplied in many countries and regions through these sales networks to meet various needs.

RF Jumper harness termination process example using MHF® connector

-

Cable processing process example

After cutting the RF coaxial cable to the required length, the RF coaxial cable is processed (three-step stripping) for the MHF® plug connector termination.

After setting the cable size and stripped dimensions in advance, insert the RF coaxial cable into the rotating blade. The blades rotate and the cable will be striped in three steps.

(*Strip dimensions vary depending on the plug used)

-

RF coaxial cable termination process example

Set the three-step stripped RF coaxial cable on the pre-assembled MHF® plug and close the contact spring together with the plug ground shell. The center conductor and the signal will be electrically connected when the contact spring sandwiches the center conductor of the RF coaxial cable.

Connect the cable outer conductor and the plug shell electrically by bending and closing the nails of the shell. Properly crimping the nails to the outer conductor and the jacket of cable will prevent the cable from slipping and will provide adequate cable retention force without soldering.

-

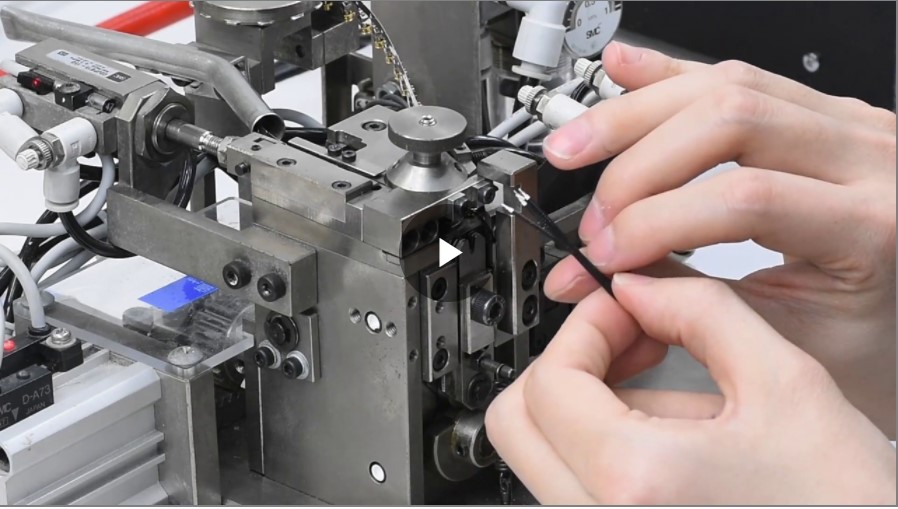

Example of cable connection process using semi-automatic machine

I-PEX Micro RF Coaxial Connector Jumper Harness (MHF® Harness) Product

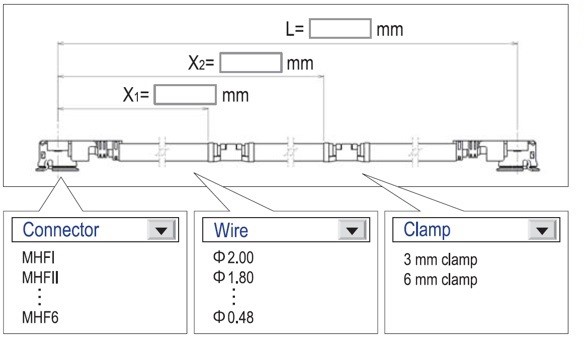

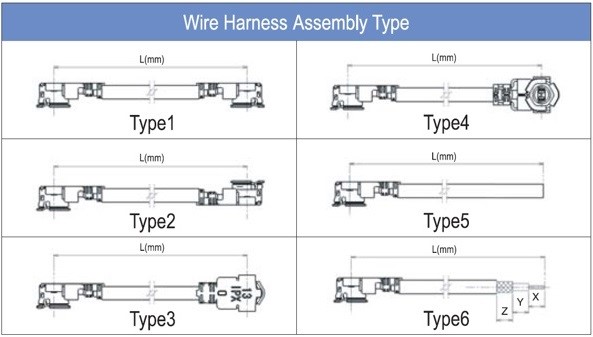

I-PEX sells completed MHF® harnesses in multiple configurations MHF-to-MHF, blunt cut, strip and tinned. Other value-added options include orientation in 90-degree increments, jacket cut-outs or windows for grounding, adding MP-A clamps or a secondary process at the customer's facility.

I-PEX specializes and leads in high-speed automated MHF® harness production. Using custom Fully Automated Machines (FAM), I-PEX FAMs will cut, strip, crimp, check orientation, and perform mechanical and electrical checks. Completing tens of thousands of harnesses per day, I-PEX MHF® automated equipment have unparalleled Defects Per Million Opportunities (DPMO) of less than 1.