The I-PEX ESTORQ® is a torque sensor that can easily be incorporated into any device or application.

ESTORQ® is Easy to Incorporate

-

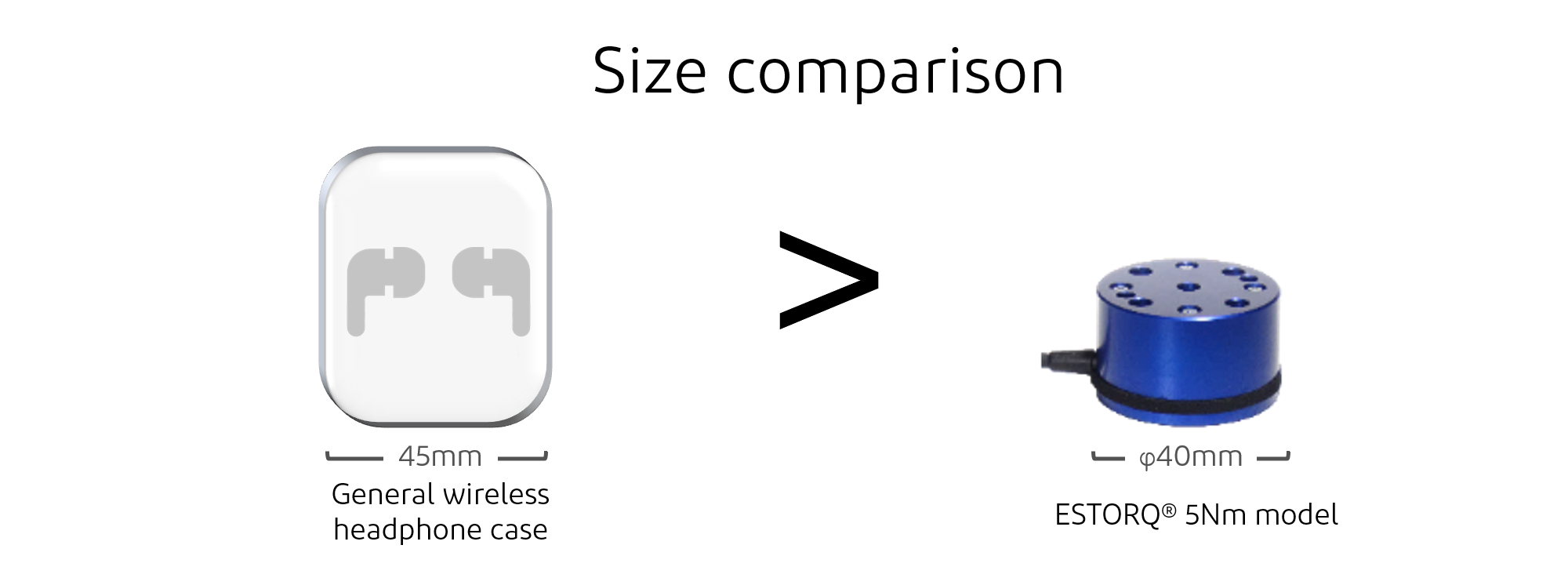

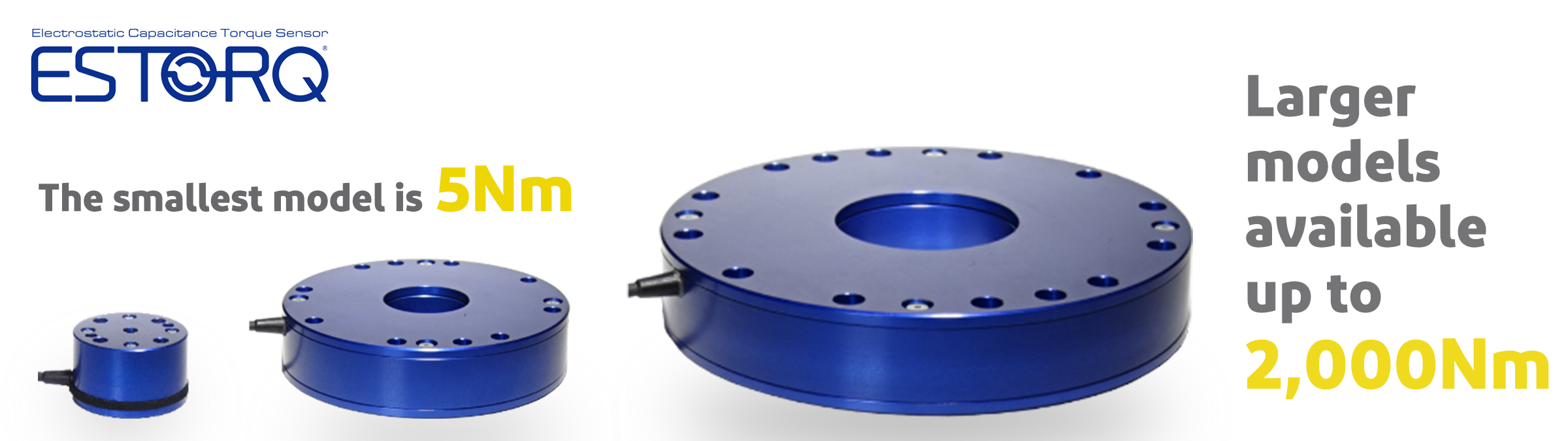

Achieves compactness and weight reduction by the electrostatic capacity method

-

Customizability

It is possible to incorporate a *built-in microcomputer into the sensor.

*Built-in microcomputer is available from Φ70×H24mm model

-

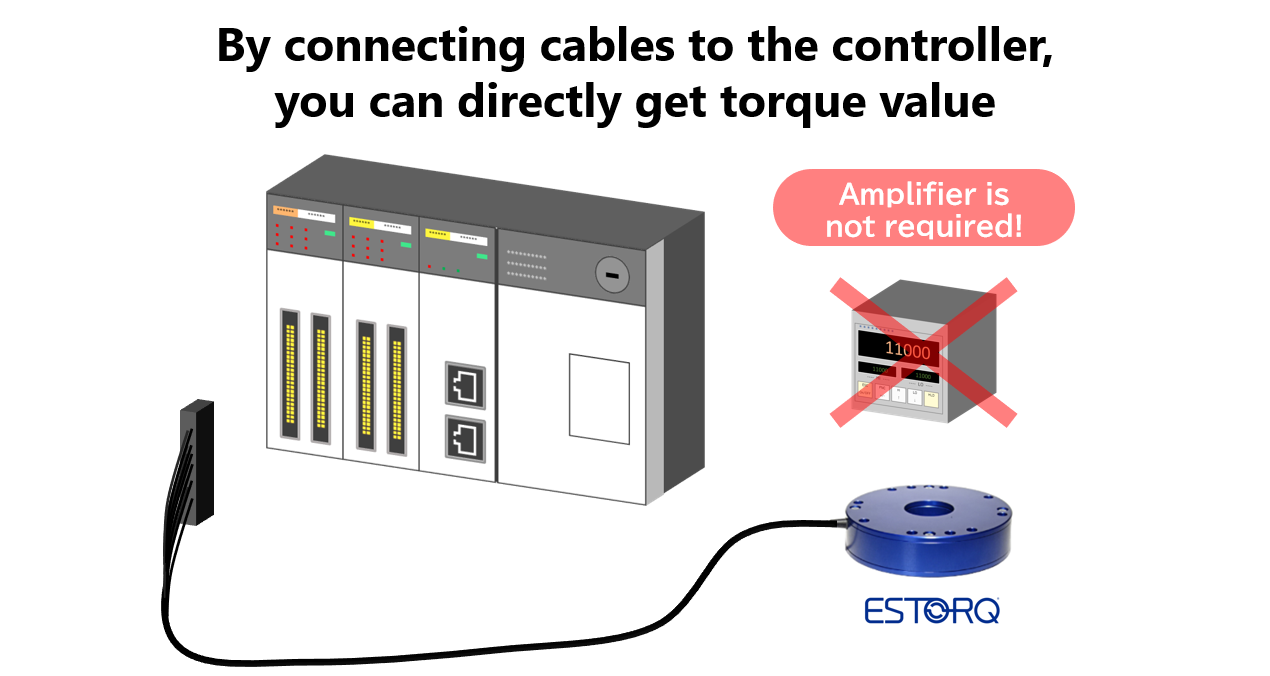

No External Amplifier Required

It is easy to use because it does not require an external amplifier to correct the torque value.

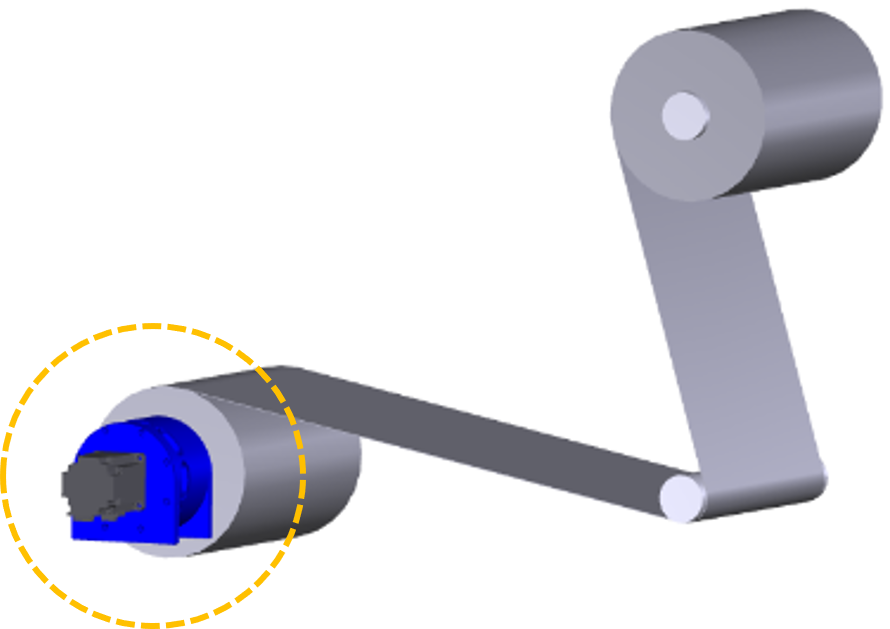

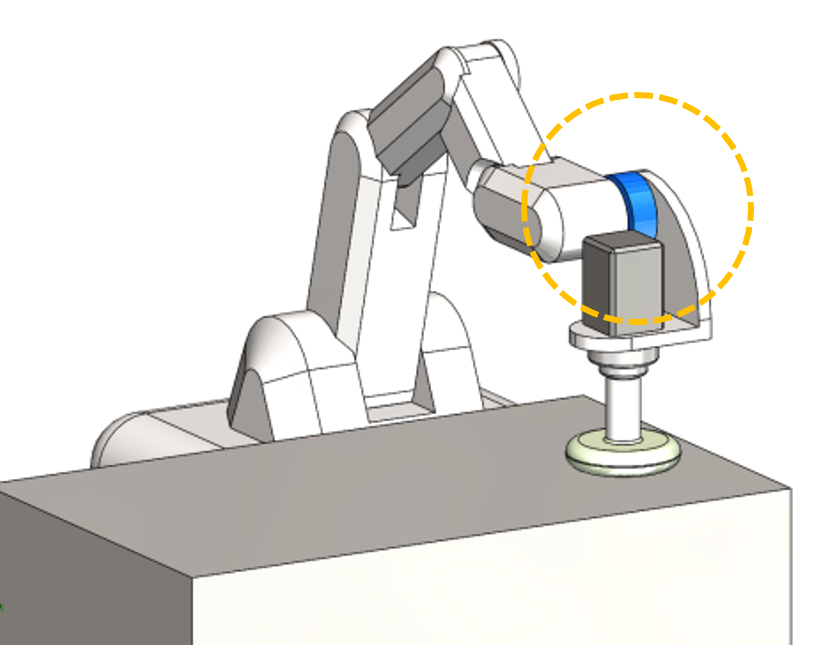

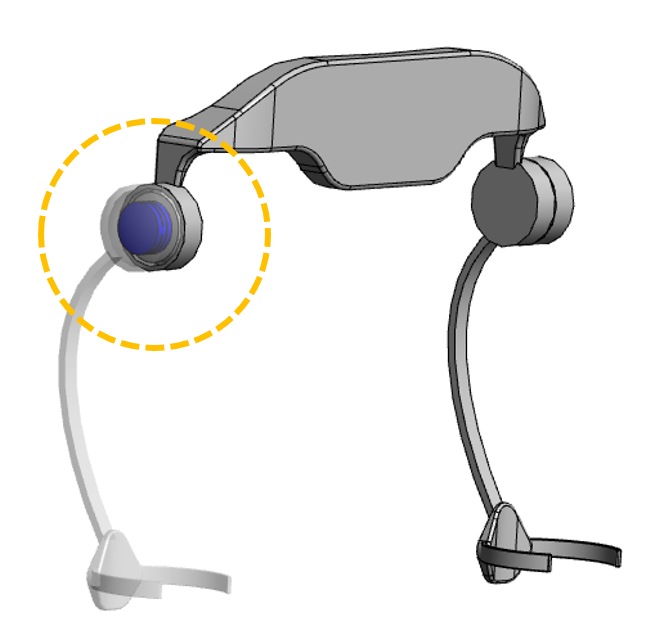

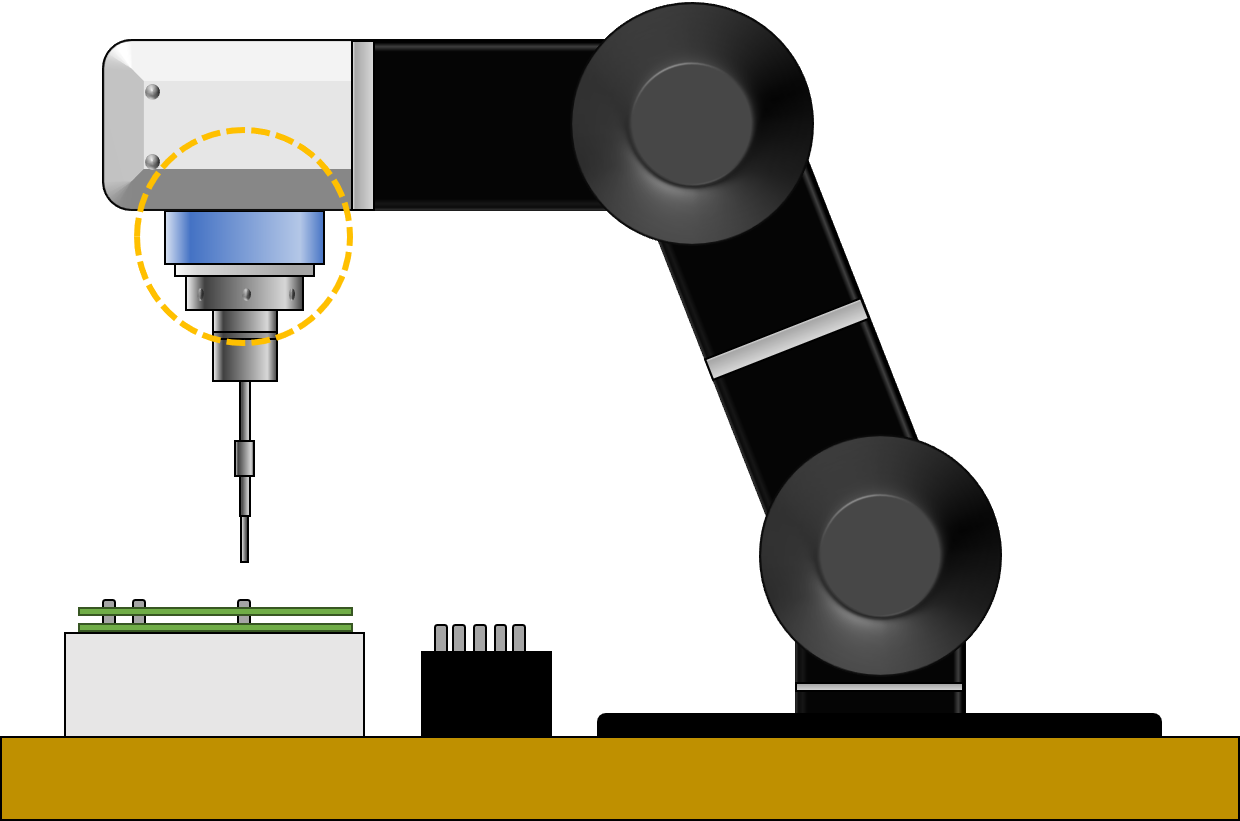

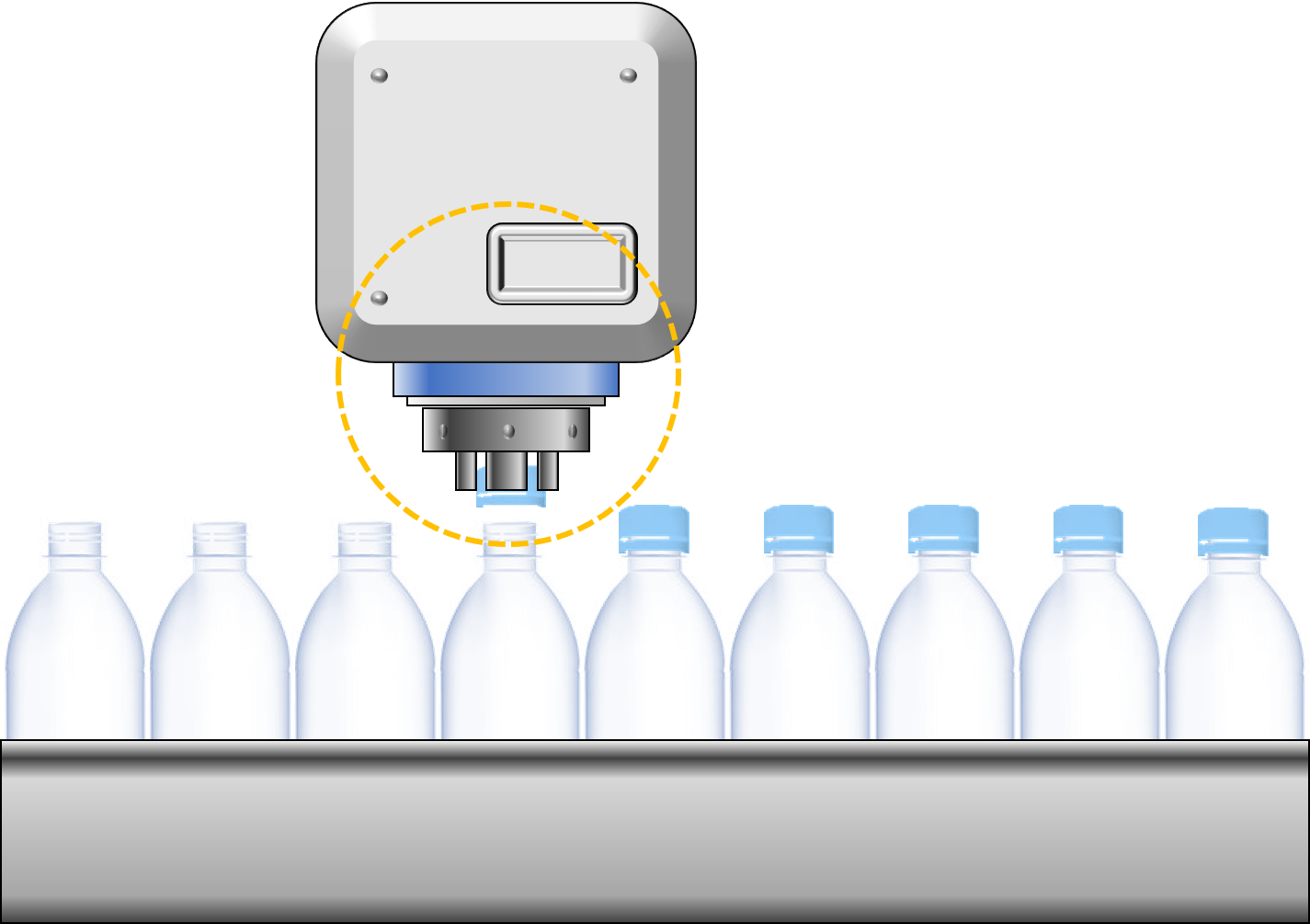

Application Examples

The ESTORQ® sensor can be incorporated into various manufacturing equipment and machines, as well as various applications. By incorporating ESTORQ® in parts closer to the drive part of each device, such as joints and links, it enables detection of minor torque value that cannot be detected by the electrical current value of the motors or actuators. Below is video of an electric hand equipped with ESTORQ®.

Demonstration video of electric hand equipped with ESTORQ®- crisps ver.

Demonstration video of electric hand equipped with ESTORQ®-eggs ver.

-

Other examples

|

Tension control for winders, etc.

|

Training equipment load measurement

|

|

Pressing control

|

Power assist control

|

|

Screw tightening device

|

Cap tightening device

|

Technology to Ensure Safety and Quality of Products

We provide high product quality through analysis technology, mass production equipment, production technology for jigs, etc., including digital production control.

- Supports various calibrations, accuracy inspections, and characteristic confirmations

- Digital management using QR code achieves material management, prevention of erroneous input, and optimum production

- Quality stabilization and stable supply utilizing flexible production by in-house mass production of equipment, as well as equipment production at partner companies

- Analysis technology to control the deformation of the micro-level housing and support for a wide variety of products

Product specifications

| Specifications | Remarks | |||||||||

| Power supply | DC 5V | |||||||||

| Rated Force | 5,10N・m | 50N・m | 100N・m | 150N・m | 200N・m | 250N・m | 300N・m | 500N・m | ~2,000N・m | Measurement Range |

| Out Put Form | RS422/RS485/Analog voltage | |||||||||

| Interface | USB/Connector/Loose Wires | |||||||||

| Consumption Current | 120mA | Peak value | ||||||||

| Operating Temp. Limit | 0~80℃ | No Condensation | ||||||||

| Nonlinearity | Below 1.5%FS | |||||||||

| Hysteresis | Below 1.5%FS | |||||||||

| Resolution | 10bit | |||||||||

| Frequency Response | 5kHz(RS422)/3kHz(RS485) | |||||||||

| External Dimension | Φ40×H24mm | Φ60×H24mm | Φ100×H24mm | Φ130×H24mm | Φ150×H24mm | Φ240×H37mm | ||||

| Product Weight | 130/50g | 350/130g | 890/330g | 1020/600g | 1190/700g | 9600/3600g | Steel/Aluminum | |||

| Protection Level | IP65 | |||||||||

| Micro computer | Built in / External *Built in Type is more than φ70×H24mm | |||||||||

Above is standard Spec. Possible to customize it to customer’s required spec.

Possible to provide Above 2000N・m. Please contact

Above is tentative Specification and it maybe changed in future .

Inquiries

In addition to the above assumed usage examples, we propose to incorporate torque sensors into various machine and equipment applications.

If you have any problems with minor torque measurement that cannot be detected by the motor electrical current value or having trouble with how you install the torque sensor, please feel free to contact us.