Design for Connectivity in Portable Medical Devices

Connectivity is at the core of the devices transforming healthcare, yet interconnects – or, connectors – are often an afterthought. Selecting the right connectors in the initial design process supports better overall performance and functionality.

MedTech designers face some of the toughest design challenges in the electronics industry. Portable medical devices must be compact and lightweight enough to be moved easily, while tolerating the vibration, shock, and impact of frequent transport. Because these products operate within a larger network of connected devices and systems, electromagnetic interference (EMI) and interoperability should also be considered early in the design process.

In addition to the usual design considerations like size, torque, pin count, and locking mechanism, connectors used in medical devices must withstand moisture, dust, chemicals, and high temperatures. They must be easy to use and durable enough to last thousands of mating cycles, all while meeting the industry’s stringent regulations.

Maximizing Wireless Connectivity

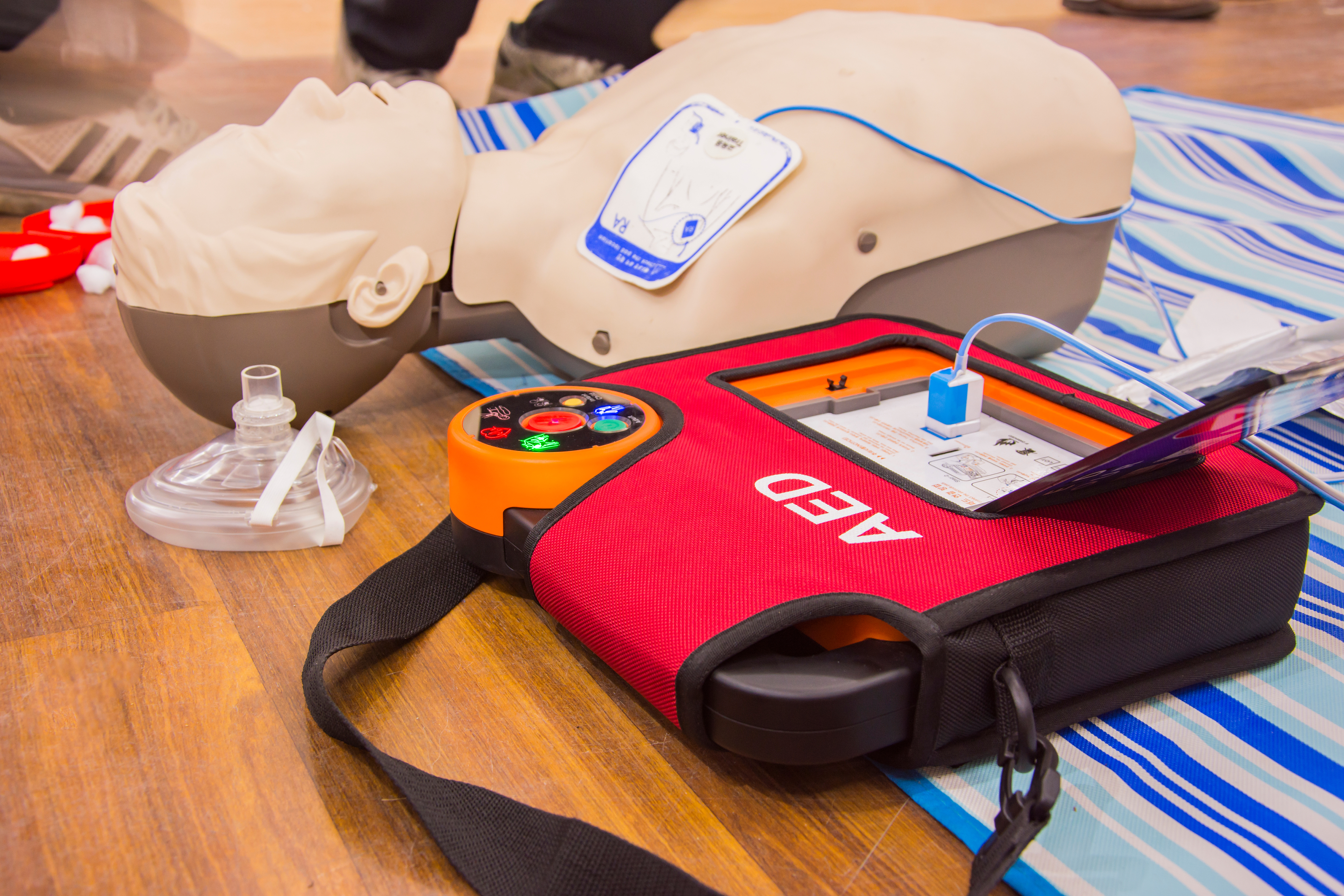

Portable medical devices have to move data from the point of care – whether that’s a hospital room, ambulance, or patient’s home – to a cloud or an internal server where it can be securely accessed by healthcare providers. Bluetooth, cellular, and Wi-Fi are currently the most commonly used wireless technologies for this purpose. Determining which is best suited to an application depends on how and where a device will be used, amount of data to be sent, and connection frequency, among other factors.

Bluetooth is widely deployed in healthcare applications due to its ease of use and low power consumption. Drawbacks include low-speed data transmission at limited range. New Wi-Fi 6/6E technologies offer stable, higher-speed, large-capacity communication. However, Wi-Fi in general struggles to maintain stable connections while devices move between indoor and outdoor locations.

Cellular networks offer more widespread coverage, reliability, and seamless interoperability with existing IT infrastructure. Disadvantages include cost, higher power consumption, and security concerns. Maximizing device connectivity is a combination of choosing the right electronic components, including interconnects, and the most suitable wireless technology for the application’s requirements.

The Need for High-Speed, High-Quality Data Transmission

While some medical equipment requires straightforward device-to-device communication, portable diagnostic equipment must transmit detailed, accurate, and high-resolution data at very high speeds. Factors like crosstalk, distortion, and noise can degrade signal quality and cause unacceptable delays or errors, impacting patient care in real-time. Components like high-frequency printed circuit boards (PCBs) are uniquely designed to maximize signal integrity. Fully shielded connectors also ensure signal integrity and allow for connectors to be placed near the on-board antennas used for wireless connectivity.

I-PEX connectors have a successful track record within a variety of medical devices.

Learn more about our entire product line: https://www.i-pex.com/product

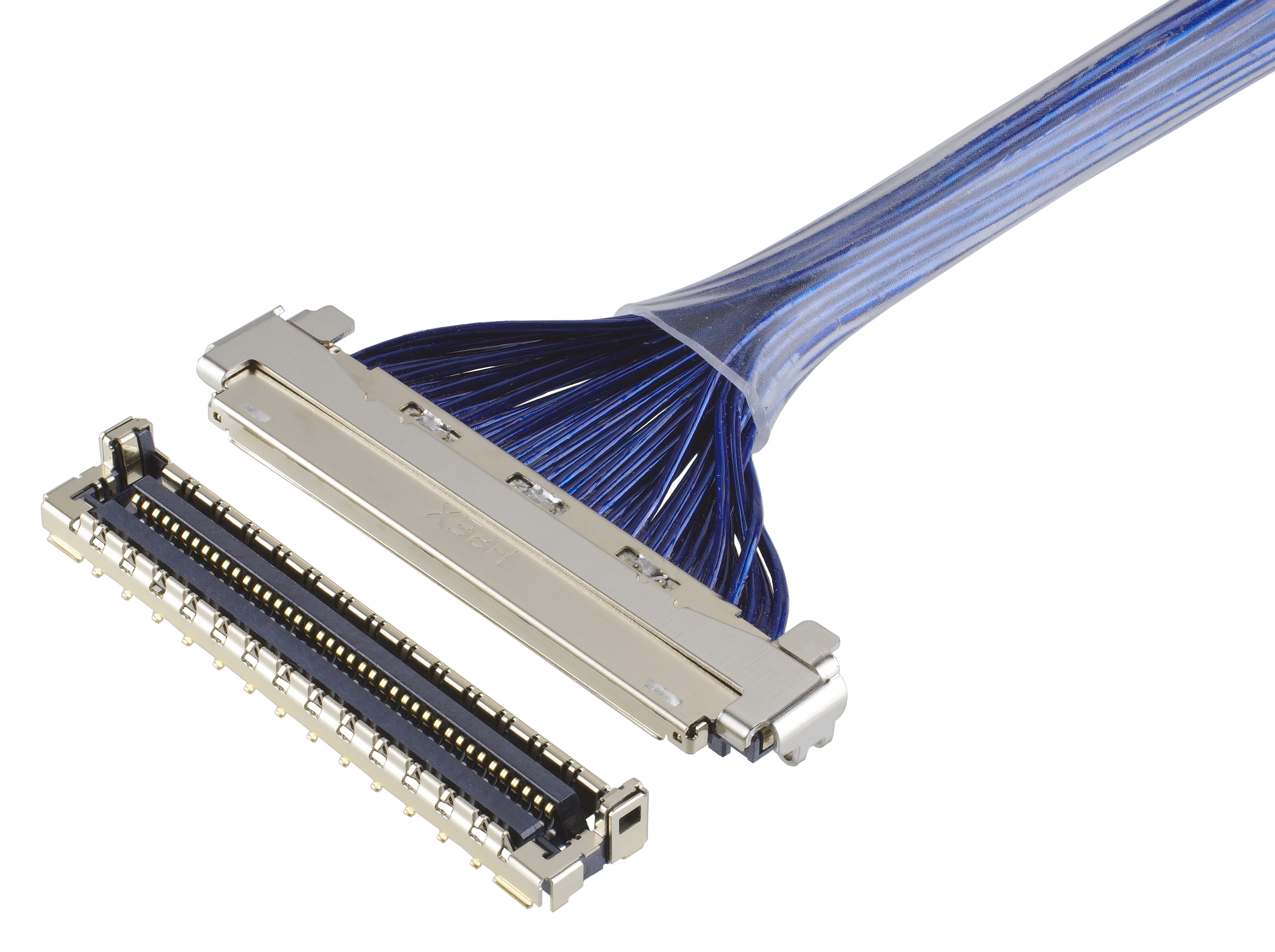

Connectors for Portable Ultrasound Probe Assemblies

Interconnects for ultrasound equipment must deliver reliable high-speed connectivity to enable detailed high-quality images in a variety of challenging conditions. A single ultrasound probe assembly requires many coaxial wires that send signals from the individual transducers to the signal processors, making flexible components a requirement.

Read more: https://www.i-pex.com/library/article/cable-connectors-ultrasound-probe-assemblies