Discover On-Board Optical Module LIGHTPASS®-EOB 100G vol. 2

I-PEX has developed the LIGHTPASS®-EOB 100G on-board optical module. This article describes the detailed contents of that optical module.

To check out for previous chapter, visit the article of vol.1.

2: Ultra-small optical transceiver engine

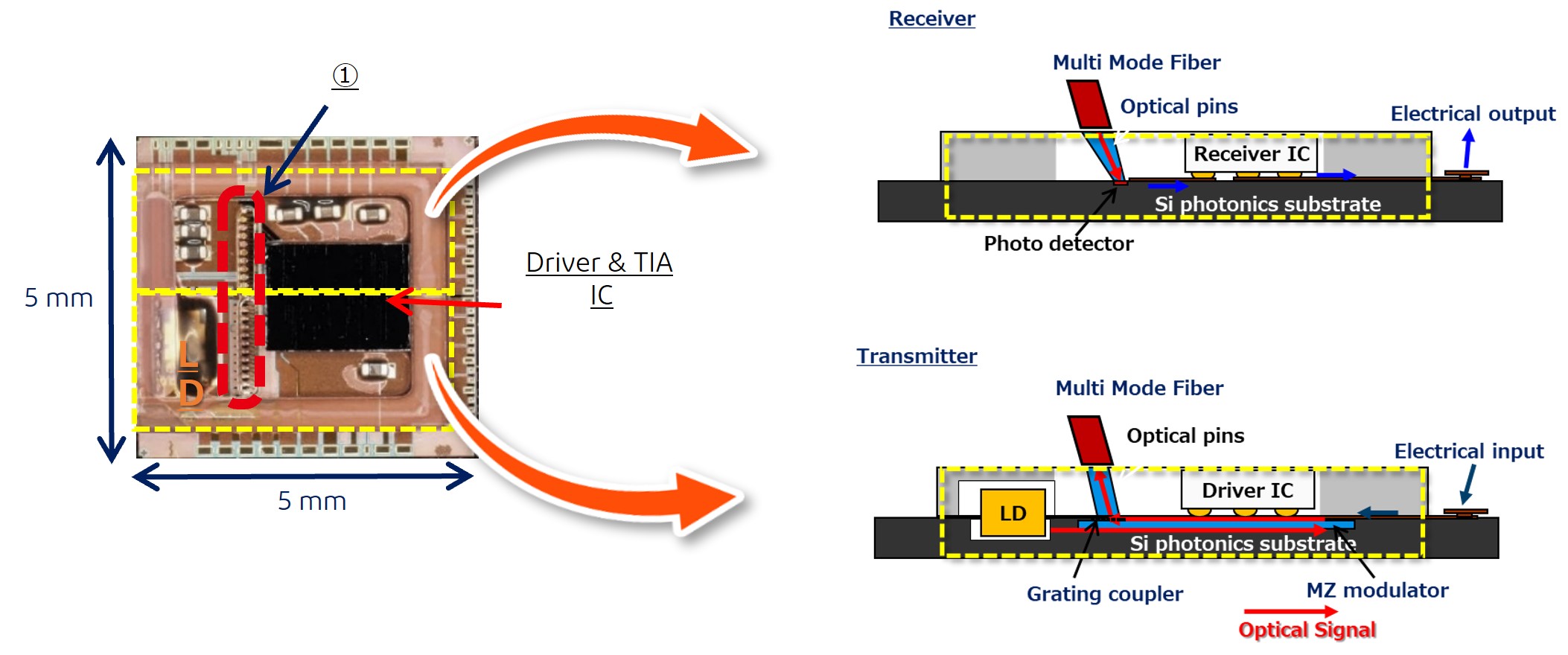

The optical IOCore® is a 5 mm square optical transceiver chip manufactured using silicon photonics technology developed by AIO CORE Co., Ltd. The optical element is on a silicon substrate and has a transmission speed of 25 Gbps per channel, enabling bidirectional communication with a total transmission speed of 100 Gbps on 4 channels of TX and RX.

1) Design Feature

- Ultra-small, high-density package (All TX and RX functions are integrated on a 5 mm2 silicon chip)

- Wide operating temperature range (Quantum dot laser is capable of operating from -40~85°C)⇒ With plans to be expanded to 105°C

- High reliability (Uses high-efficiency and high-reliability quantum dot lasers)

- Easy fiber coupling technology (Optical pin structure with sufficient tolerance allows passive optical coupling)

- Low cost (All manufacturing processes are automated to achieve high productivity and lower cost.)

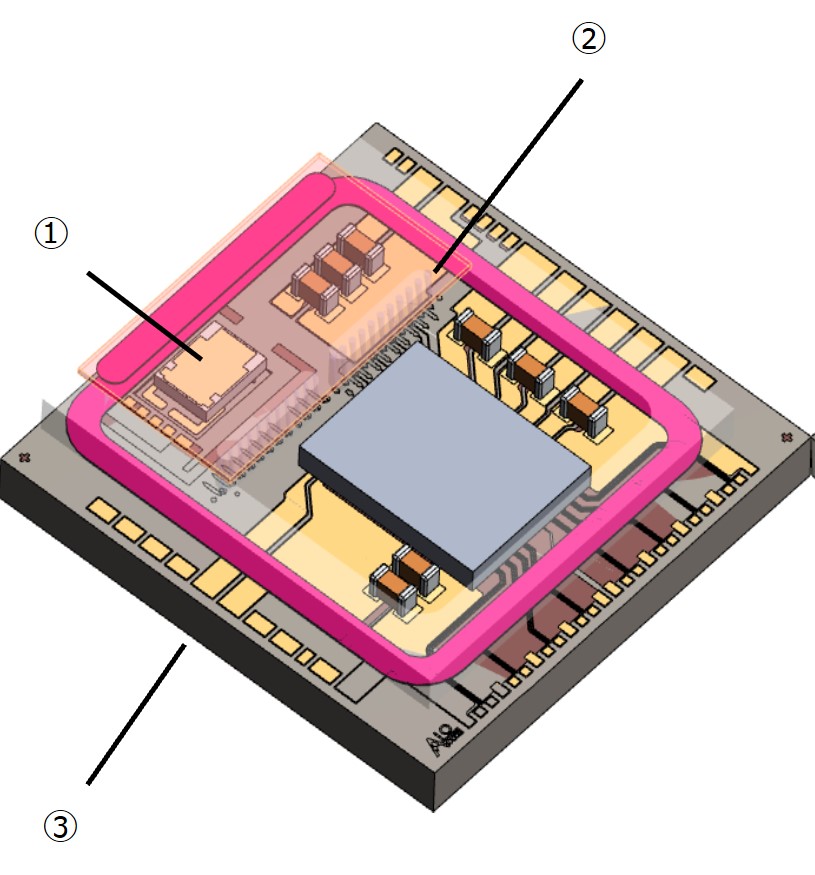

2) Structure of Optical IOCore®

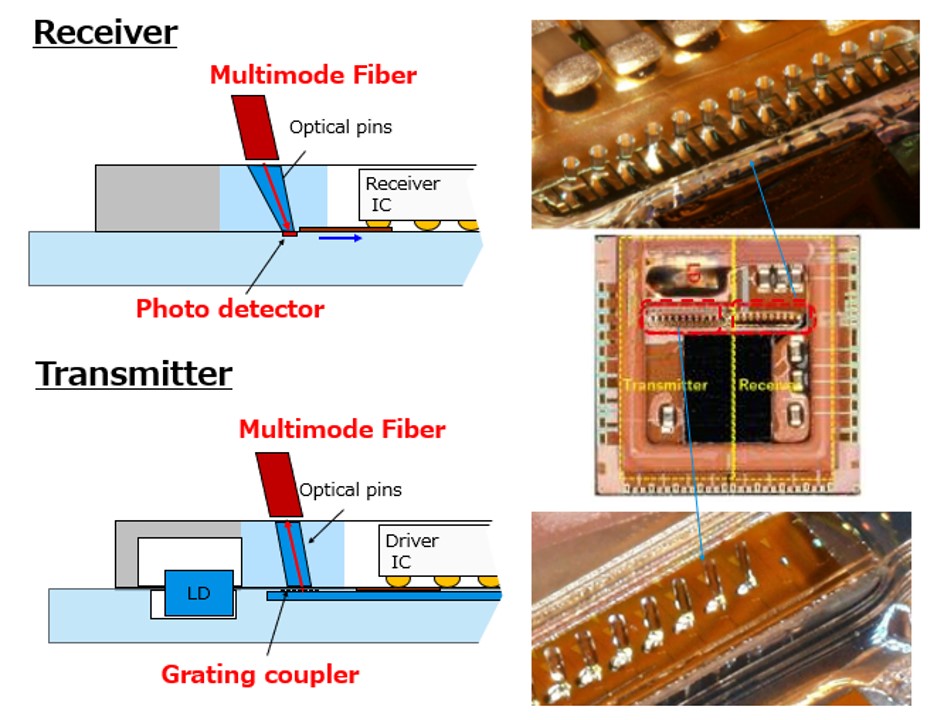

A receiver with a photodiode (PD)and transimpedance amplifier (TIA), and a transmitter with a laser diode (LD), modulator, and grating coupler, are both built into a 5 mm 2 silicon chip.

On the receiving side, optical signals from the optical fiber at the top are received by the PD mounted on the silicon substrate through optical pins, and electrical signals are transmitted to the module substrate through the electrode on the chip end via the TIA.

On the transmitting side, the light from the LD is modulated and converted to an optical signal based on the electrical signal drawn from the electrode at the end of the chip. Through the optical waveguide, the signal is bounced up to the optical pin by the grating coupler and drawn into the optical fiber equipped on the top.

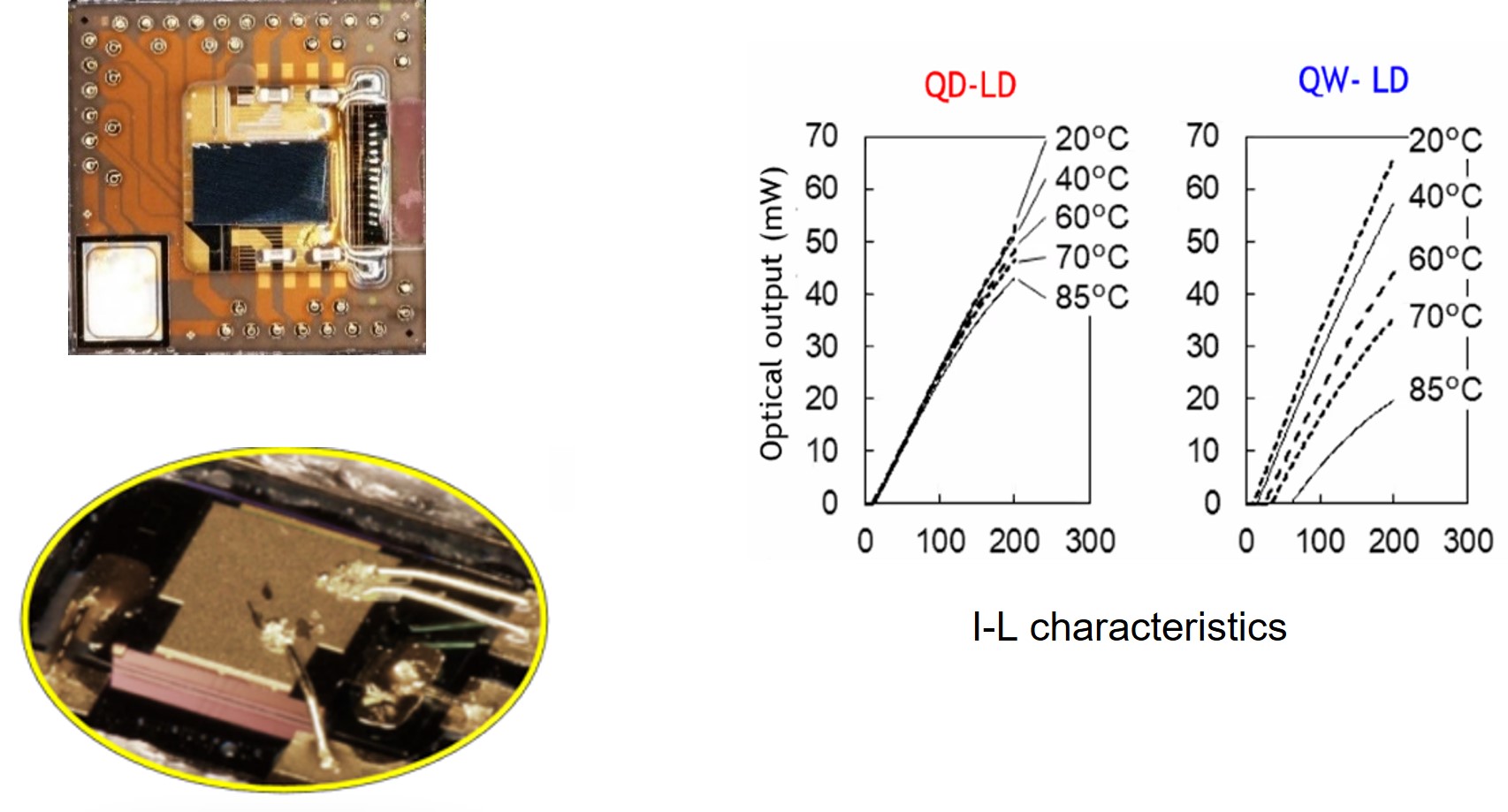

3) Quantum Dot Laser Diode (QD-LD)

We use a quantum dot laser (QD-LD) as a light source, capable of maintaining high output even at high temperatures. QD-LD exhibits high reflection resistance and favorable Relative Intensity Noise (RIN) characteristics, minimizing issues related to noise and signal quality in communication systems. Additionally, it is more stable and has less performance variation with temperature compared to conventional LDs.

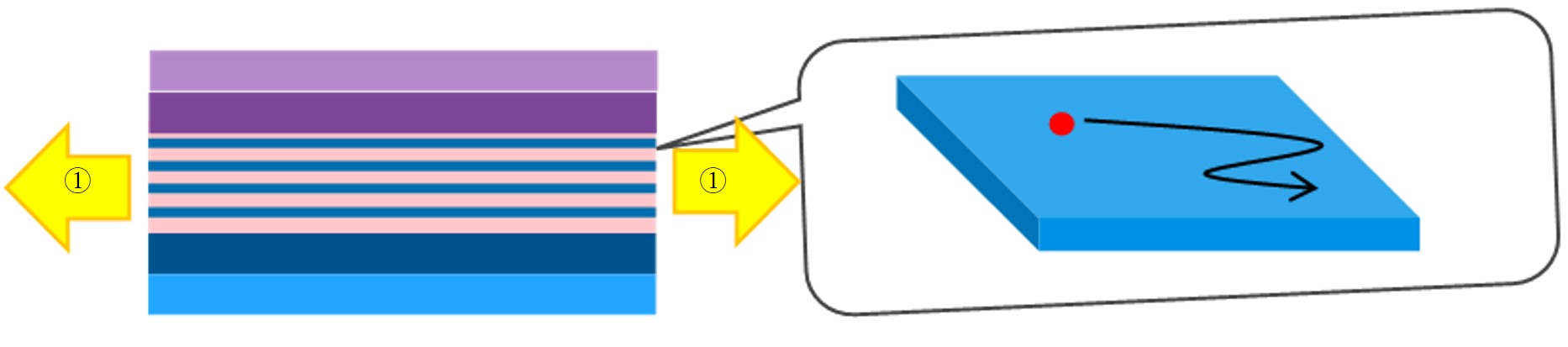

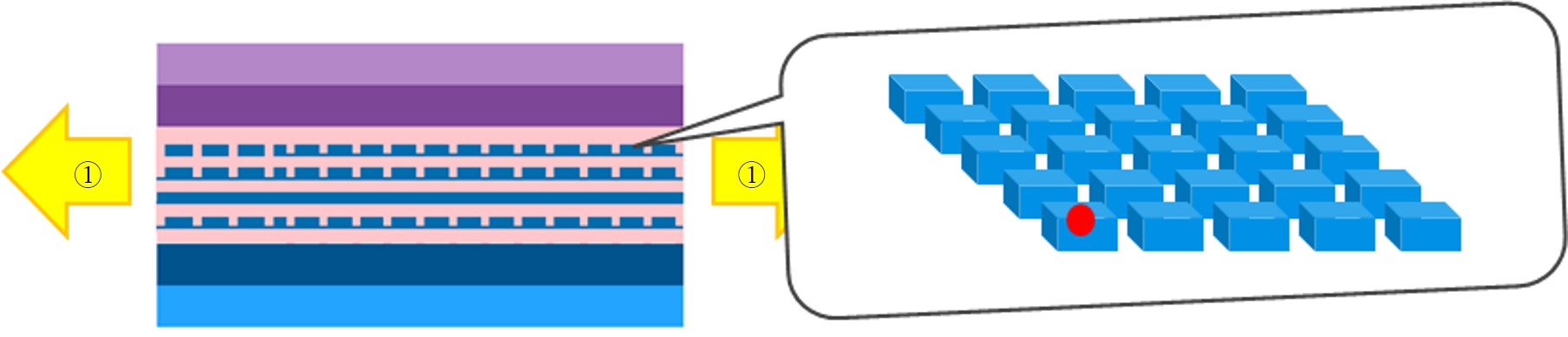

Conventional Laser Diode (Quantum Well)

The active layer of conventional LDS where electrons are confined one-dimensionally. The problem arises from the degradation of characteristics at high temperatures due to increased electron mobility with temperature variation.

QD-LD (Quantum Dot)

A laser utilizing quantum dots in the active layer.

The energy of electrons confined in quantum dots is limited, resulting in minimal changes in electron states even with temperature increases, leading to a significant improvement in temperature characteristics. Quantum dots are tiny semiconductor particles with sizes on the order of 10nm, approximately the wavelength size of electrons.

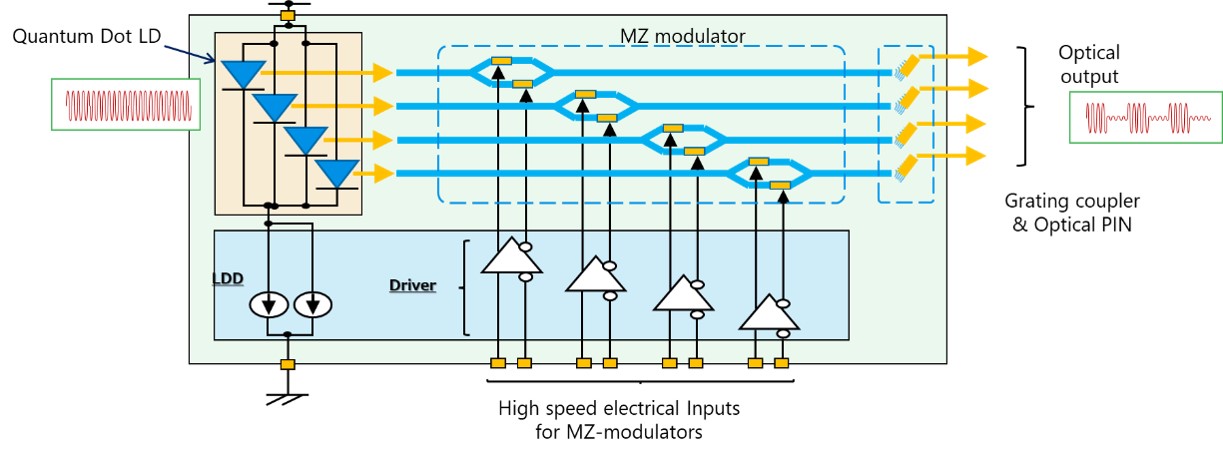

4) Transmission of Optical IOCore® (electrical to optical)

The IOCore® utilizes Mach-Zehnder (MZ) modulators with low temperature sensitivity. The modulation efficiency of the MZ modulator is given by the equation C×V (C = capacitance, V = supply voltage). Since C is independent of temperature and the modulation voltage remains constant, the frequency bandwidth remains stable over a wide temperature range. As a result, we can achieve very stable optical output waveforms with minimal jitter over a wide temperature range.

5) Optical Coupling Structure

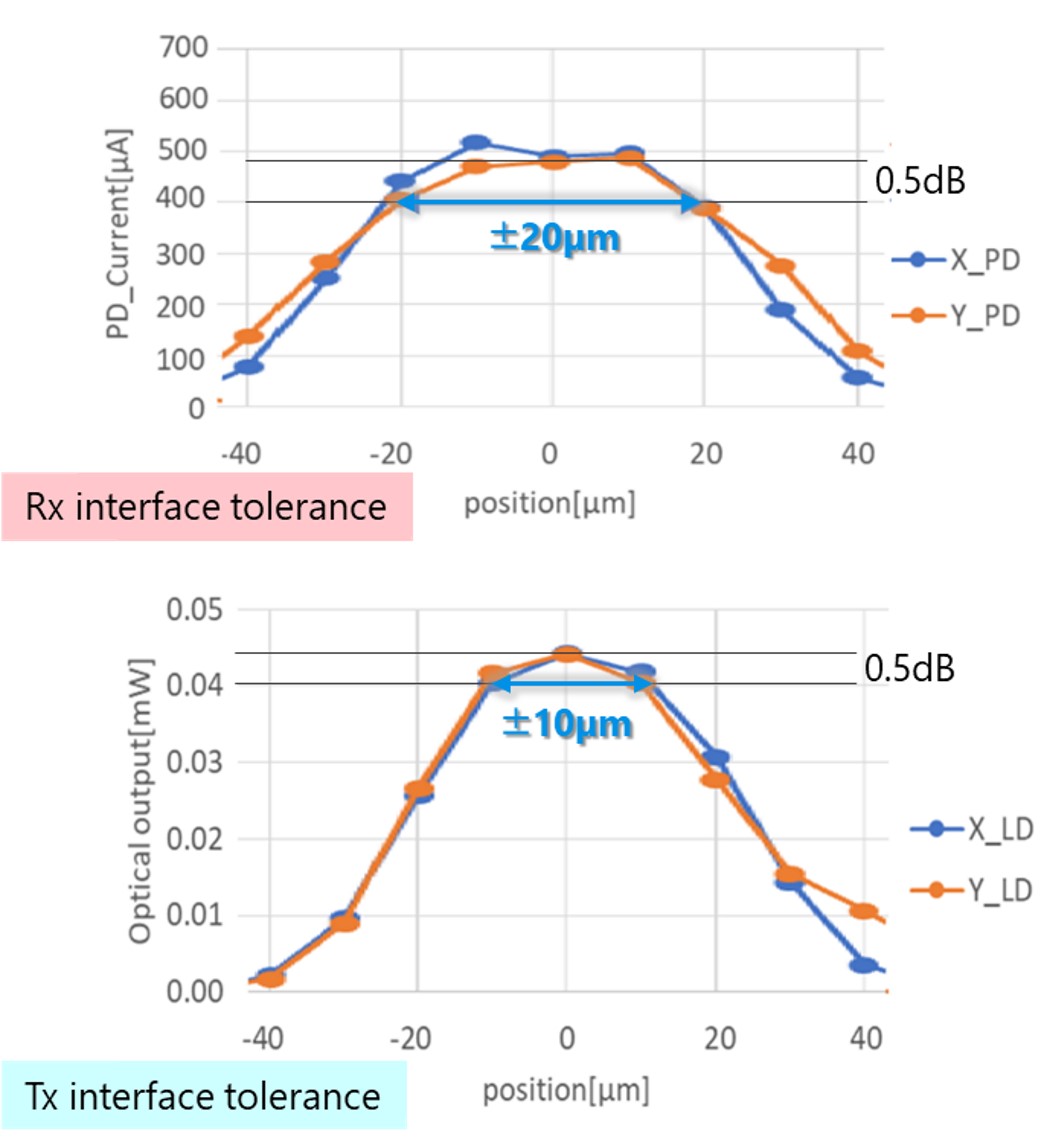

LIGHTPASS® products use optical pins at the coupling section between the optical components mounted on the silicon substrate of the optical transceiver chip and the optical fibers. Similar to the core section of the optical fiber, at the boundary surface of the optical pin, light is reflected and contained within, preventing leakage. Thus, on the receiving end, the optical pin serves a funnel-like role in connecting the light signal from the optical fiber to the photodetector, while on the transmitting end, it serves to convey the light signal reflected from the grating coupler to the optical fiber. We ensure coupling tolerances of ± 10μm or more on both the receiving and transmitting ends.

6) Temperature Sensitivity of Optical Coupling

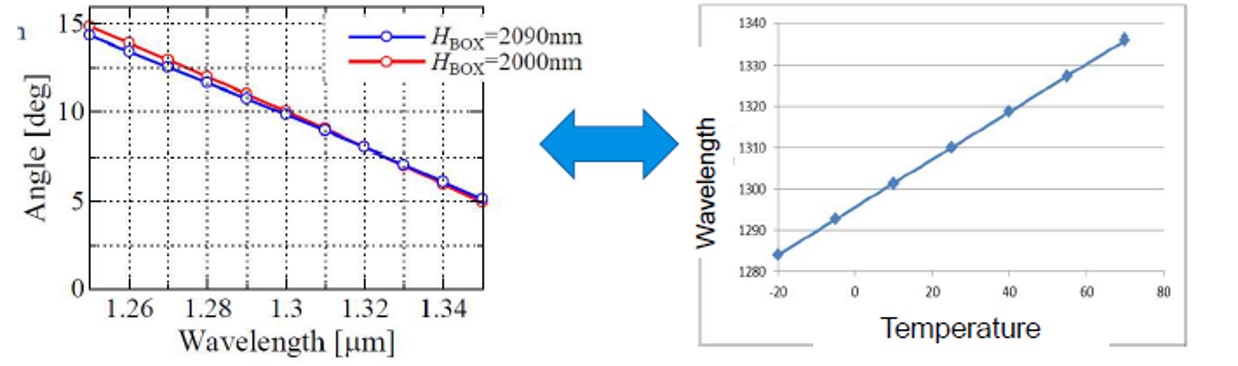

The optical coupling section on the transmitting side, namely the light emission section from the optical pin, exhibits temperature sensitivity. This is due to the temperature-dependent wavelength of the LD, which shifts by 0.6 nm per 1°C change in temperature. Furthermore, the emission angle of light from the grating coupler is wavelength-dependent, shifting by 0.083° per 1 nm change in wavelength.

As a result, the emission angle from the grating coupler changes by 0.05° per 1°C change in temperature, leading to a variation of ± 3.6° in angle over a temperature range of -40°C to 105°C. Considering the numerical aperture of the optical pin, which is 0.4 or higher, and the maximum incident angle of 23.6°, a sufficient incident angle is ensured. Therefore, even if the angle changes due to temperature variations, the light entering the optical pin can convey the light signal to the upper fiber without leaking externally.

QD-LD : Wavelength shift 0.6 nm/°C

|

Radiation angle changes: 0.05 degree/°C |

in the range of - 40 ~ 105 °C

|

7) Optical Axis Analysis of Optical Coupling

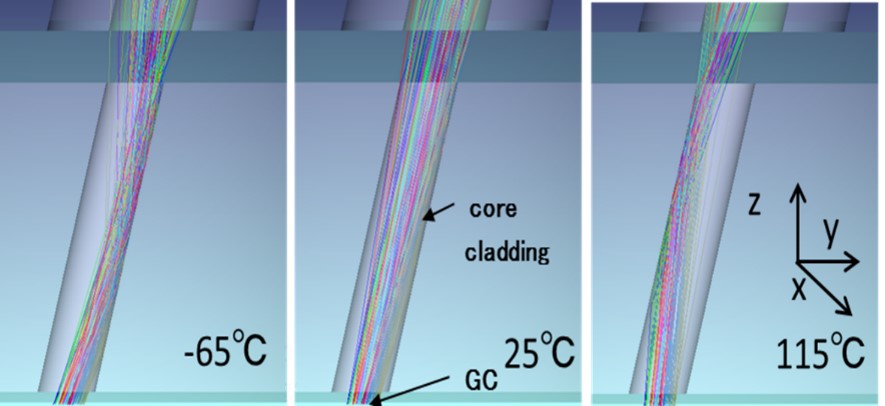

Based on the optical axis analysis, it has been confirmed that the light emitted from the grating coupler undergoes changes without leaking from the optical pin and is effectively transmitted to the upper fiber.

To learn more about the LIGHTPASS product family, visit:

1: Ultra-thin optical module

2: Ultra-small optical transceiver engine

3: High-speed, low-profile, electrical connector

4: Ultra-low-profile fiber array

5: High heat dissipation module structure

6: Ultra-thin optical transceiver module evaluation results

Conclusion