Board-to-Board (FPC) Connectors

High data rate / high frequency options with 360° EMI shielding making them ideal for 5G mmWave / Sub-6, USB4, Thunderbolt 4 and eDP HBR3 applications.

Contents :

Why Select I-PEX Board-to-Board Connectors?

1) High-speed transmission 20+Gbps/lane

2) 5G mmWave and Sub-6 GHz

3) Full EMI Shield

4) Install an Independent Power Terminal

- Connectors that can use hold-down as a power supply contact

- Dedicated Connector with Power Terminal

- Connector for Power Supply

Why Select I-PEX Board-to-Board Connectors?

1) High-speed transmission 20+Gbps/lane

I-PEX has applied the same technology we used in the development of coaxial connectors, “signal integrity × ultra-miniaturization,” to our high-speed transmission to board-to-board (FPC) connectors. In addition to the advantages of general board-to-board (FPC) connectors, we offer connectors that are ideal for internal connections that require high-speed transmission for mobile devices.

Corresponding connector : NOVASTACK® 35-HDP, NOVASTACK® 35-HDH

Search Board-to-Board (FPC) Products View Product Matrix Back to top

2) 5G mmWave and Sub-6 GHz

I-PEX 5G board-to-board connector solutions lead enablement of 5G device deployments globally. The shielded board-to-board solution solves EMI problems and improves overall EMC. Additional improvements include best in class electrical performance (VSWR/IL) and superior current rating. Both are crucial to the efficient operation of 5G devices.

Corresponding connector : NOVASTACK® 35-HDN, NOVASTACK® 35-HDP, NOVASTACK® 35-HDH

Search Board-to-Board (FPC) Products View Product Matrix Back to top

3) Full EMI Shield

| General connector without metal shell | I-PEX connector with metal shell |

|

|

Connectors from I-PEX have a structure that encloses the signal contacts/soldered parts of the plug/receptacle by providing shells on both the plug/receptacle. These connectors have excellent grounding characteristics due to the structure in which the plug shell/receptacle shell connect with each other at multiple points when the connector is mated. Grounding takes place on the board at multiple points, and the structure in which all signal contacts of the plug/receptacle are enclosed by a shield giving the connector excellent i360-degree EMI shielding performance.

Interference with other high-frequency signals can be suppressed, allowing designers to place connectors near the antenna.

Corresponding connector : NOVASTACK® 35-HDN , NOVASTACK® 35-HDP , NOVASTACK® 35-HDH

Search Board-to-Board (FPC) Products View Product Matrix Back to top

4) Install an Independent Power Terminal

We have connectors that achieve ultra-miniaturization while ensuring the power supply required for each application of mobile devices.

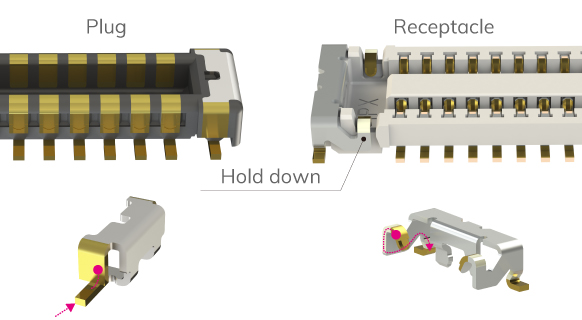

4-1) Connectors that can use hold-down as a power supply contact

Because the hold-down feature of the board-to-board connector is metal, it can be used as a power supply contact, as well as adding additional robustness to the connector. The guide shape of the connector makes for smooth insertion and mating. Since the signal contacts do not have to be used for power supply, reducing the number of pin counts is effective in saving space.

Because the hold-down feature of the board-to-board connector is metal, it can be used as a power supply contact, as well as adding additional robustness to the connector. The guide shape of the connector makes for smooth insertion and mating. Since the signal contacts do not have to be used for power supply, reducing the number of pin counts is effective in saving space.

Corresponding connector : NOVASTACK® 35-P, NOVASTACK® 35-PH

Search Board-to-Board (FPC) Products View Product Matrix Back to top

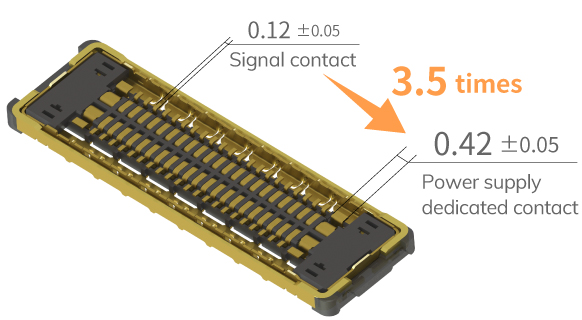

4-2) Connector with Dedicated Power Terminal

The dedicated power supply is 3.5 times wider than the signal contact and uses a Corson alloy that excels in electrical conductivity and heat conduction. (Signal terminal width: 0.12 mm, power supply dedicated contact width: 0.42 mm)

The dedicated power supply is 3.5 times wider than the signal contact and uses a Corson alloy that excels in electrical conductivity and heat conduction. (Signal terminal width: 0.12 mm, power supply dedicated contact width: 0.42 mm)

Corresponding connector : NOVASTACK® 35-HDP

Search Board-to-Board (FPC) Products View Product Matrix Back to top

4-3) Connector for Power Supply

| Input current | Power contact : 6.0 A / pin Signal contact : 1.0 A / pin |

| Input |

Power contacts 6.0A x 4 pins and signal contacts 4 pins are equipped, and the hold-down and metal guide ensure mating easability and robustness.

Corresponding connector : NOVASTACK®-B