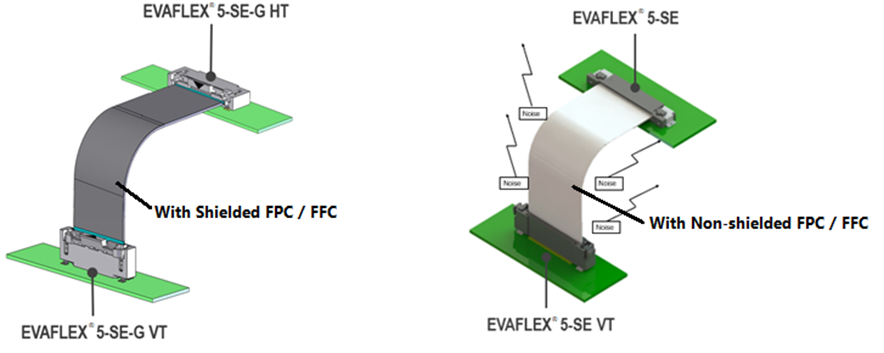

EVAFLEX® 5-SE-G VT, EVAFLEX® 5-SE-G HT – 0.5mm pitch FPC / FFC connector with grounded pins, high temperature resistance

One of the easiest connectors to handle in many of our I-PEX connector series is the FPC / FFC connector.

The EVAFLEX® 5-SE-G VT and EVAFLEX® 5-SE-G HT connectors (VT = Vertical Type, HT = Horizontal Type) feature:

- Auto-locking mechanism

- Applicable for high temperature environments

- Compatible with common FPC/FFC connectors

- Grounding function, shielded FPC/FFC applicable

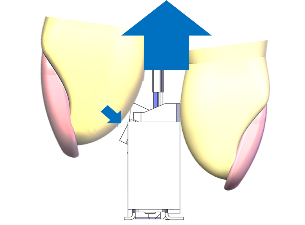

1. Auto-locking mechanism – ideal for manual or robotic assemblies

After mounting to a PCB, one-action mating by inserting and locking FPC / FFC connectors achieves workability, productivity, and contributes to factory automation.

(When removing the FFC/FPC connector, it can be extracted while pressing the lock button, enabling one-handed operation.)

A mechanical lock that firmly hangs on the notch of the FPC/FFC reinforcing plate can be used for vibration and routing, helping it achieve a strong connection.

When locking connectors, the click sound reduces a half-mated condition.

- Unlike conventional FPC/FFC connectors, there is no need to open and close the actuators, so assembly tact time is improved and the risk of lock lever damage is reduced.

In addition, due to soaring labor costs, labor shortages, reduction of assembly costs, and reduction of risk of defects, manufacturing automation will be accelerated. Along with this, automatic insertion of connectors by robots has been increasing. I-PEX will keep working toward the realization of automation by proposing a gripper for robots that grips cables.

2. 125°C heat resistance, shock, and vibration support – evaluated under strict environmental conditions for various vehicle devices

Evaluated under rigorous test conditions required for vehicle components such as temperature cycle test, heat resistance test, vibration test and impact test.

|

Test Item |

Testing method |

Measurements |

|

|

Mechanical Performance |

Vibration |

3 mutually perpendicular directions 2 hours for each direction for a total of 6 hours |

-Contact resistance -Electrical discontinuity -Appearance |

|

Shock |

Max. G: 50G Duration: 11m sec, Direction: 6 mutually perpendicular directions Cycle: 3 cycles for each direction |

-Contact resistance -Electrical discontinuity -Appearance |

|

|

Environmental Performance |

Heat Cycling |

Temp: -55⇔+125℃ 30 mins. Transition 5 mins. MAX No. of cycles: 100 cycles |

-Contact resistance - Appearance |

|

High Temp Life |

Temp: 125℃±2℃ Duration: 1,000 hours |

-Contact resistance - Appearance |

|

|

Humidity (Steady State) |

Temp: 40±2℃ Humidity: 90~95% RH Duration: 240 hours |

-Contact resistance -Insulation resistance -Dielectric withstanding voltage -Appearance |

|

|

Humidity (Cycling) |

Temp: -10~+65℃ Humidity: 90~98% RH Cycle: 10 cycle (240 hours) |

-Contact resistance -Insulation resistance. -Dielectric withstanding voltage -Appearance |

|

|

Salt Water Spray |

Temp: 35±2℃ Salt water density: 5±1% [by weight] Duration: 48 hours |

-Contact resistance -Appearance |

|

|

H2S Gas |

Temp: 40±2℃ Humidity: 80±5% RH Gas: H2S 3±1 ppm Duration: 96 hours |

-Contact resistance -Appearance |

|

- Download EVAFLEX® 5-SE-G VT product specification from here

- Download EVAFLEX® 5-SE-G HT product specification from here

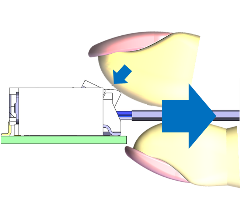

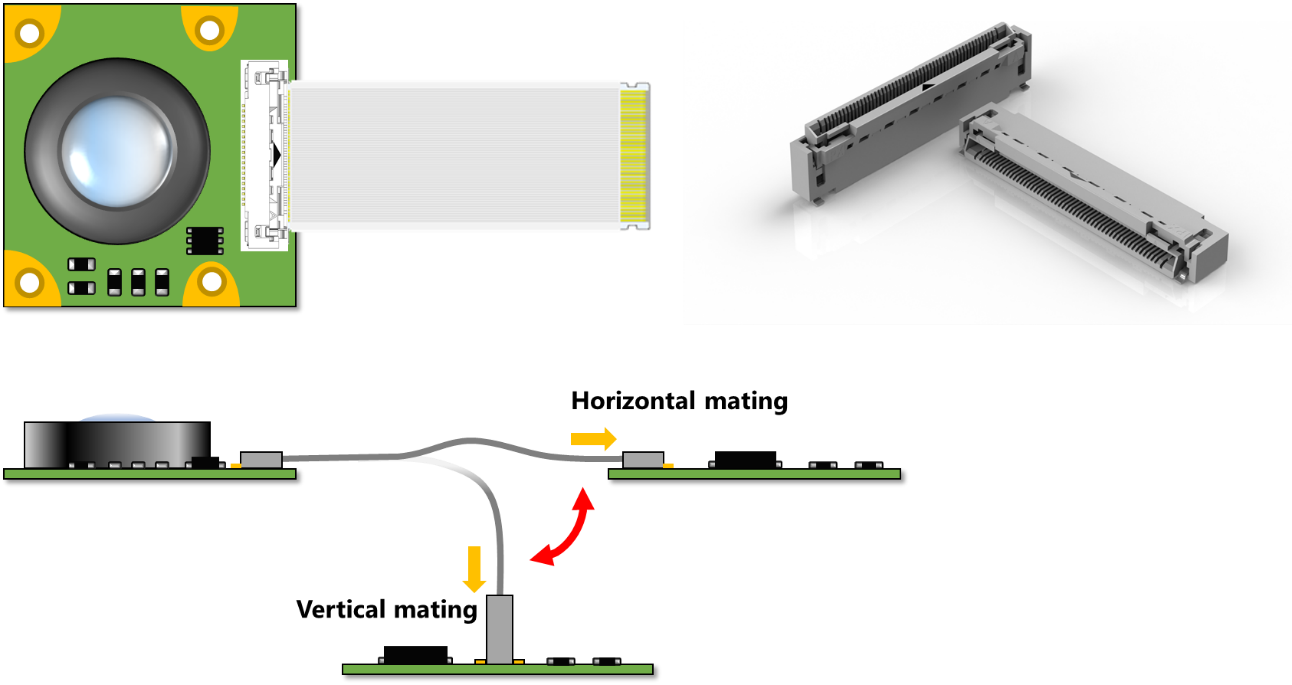

3. Common design FPC/FFC – it can help improve board design and assembly workability

These connectors have a common design that allows for selection of horizontal or vertical mating directions with common FPC/FFC designs. Since the mating direction can be changed without changing the FPC/FFC, the modules can be applied to a wider range of devices.

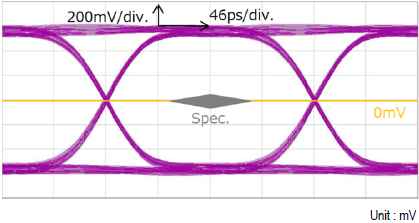

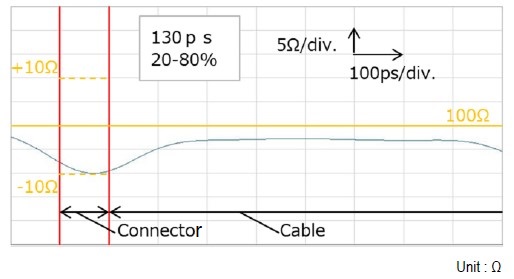

4. Grounding function, shield FPC/FFC applicable

Stable signal transmission is achieved by the grounding function and prevents electromagnetic interference for other parts and devices with shielded FPC/FFC.

Bit rate:5.4Gbps,

Rise time:130ps(20-80%),

Input Voltage:1.2Vp-p

Application examples:

- Front view camera

- LiDAR

- Radar

- Car navigation, Audio system

- Inverter (control units)

- Heads-up display