Wafer Products (KRYSTAL® Wafer)

We also provide advices on single-crystalline deposition using Underlying KRYSTAL® Wafers if you wish to use your own equipment for PZT deposition.

What is KRYSTAL® Wafer?

Superior wafers for piezoelectric MEMS, that can be single-crystallize various piezoelectric materials to be deposited by using an original ZrO2 Buffer.

KRYSTAL® Wafer Product Types

- Substrate materials: Silicon substrate, and SOI (Silicon on Insulator) substrates

- Standard substrate sizes: 6-inch, and 8-inch sizes

-

ZrO2 Buffer Wafer (ZrO2)

Zirconium dioxide or “Zirconia,” an oxidized form of the metal “zirconium” (Zr), is known for its high melting point. Its crystal structure is a Ditetragonal dipyramidal structure, categorized in the P4₂/nmc space group. This pyramid forms along the lattice constant of the material on the upper layer, and contributes to a single crystal form of that upper layer material. This is a key aspect of KRYSTAL Wafer’s single crystal technologies.

Zirconium dioxide or “Zirconia,” an oxidized form of the metal “zirconium” (Zr), is known for its high melting point. Its crystal structure is a Ditetragonal dipyramidal structure, categorized in the P4₂/nmc space group. This pyramid forms along the lattice constant of the material on the upper layer, and contributes to a single crystal form of that upper layer material. This is a key aspect of KRYSTAL Wafer’s single crystal technologies.

-

Bottom Electrode Pt Wafer (Pt/ZrO2)

Pt demonstrates low resistance and forms thin films easily, so it is often used as an electrode in film forming for piezoelectric elements. Based on the customer’s specifications, we provide Pt film formed on ZrO₂.

Pt demonstrates low resistance and forms thin films easily, so it is often used as an electrode in film forming for piezoelectric elements. Based on the customer’s specifications, we provide Pt film formed on ZrO₂.

-

Bottom Electrode SRO/Pt Wafer (SRO/Pt/ZrO2)

Strontium ruthenium oxide (SRO; SrRuO₃) is a type of ferro-magnetic metal oxide, and a Ruddlesden-popper type compound. The crystal structure is a perovskite structure, and film stability is increased by forming the film on a Pt film.

Strontium ruthenium oxide (SRO; SrRuO₃) is a type of ferro-magnetic metal oxide, and a Ruddlesden-popper type compound. The crystal structure is a perovskite structure, and film stability is increased by forming the film on a Pt film.

-

Single-Crystal PZT Wafer

These products feature well-balanced specifications, offering a high d-constant and withstand voltage, and a low dielectric constant.

These products feature well-balanced specifications, offering a high d-constant and withstand voltage, and a low dielectric constant.

-

Single-Crystal PZT with Top Electrode Wafer

At the customer’s request, we deliver SRO+Pt film formed on top of PZT film, as a top electrode.

At the customer’s request, we deliver SRO+Pt film formed on top of PZT film, as a top electrode.

New Technology Developments

-

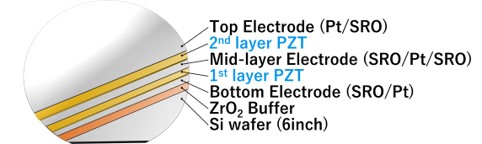

Multi-layer Single-Crystal PZT (2-layer) Wafer

Multiple layers of single-crystal PZT are deposited by applying superior deposition technology. Piezoelectric properties are improved, enabling high-power and high-precision actuator drive. (Developing with 6-inch wafer now)

Multiple layers of single-crystal PZT are deposited by applying superior deposition technology. Piezoelectric properties are improved, enabling high-power and high-precision actuator drive. (Developing with 6-inch wafer now)

-

Lead-free thin film materials

PZT film demonstrates outstanding characteristics and is used in various applications, but because this material contains a lead component, in recent years, applications are at times limited from the perspective of impact on the environment and health. We are working to develop lead-free materials that demonstrate characteristics equivalent to or better than PZT film.